Dear Guest,

Please register or login. Content don't create itself!

Thank you

-

Fork post mounts

Fork post mounts

I'm looking ideas for coming forks with the post mounts.

Please show how you have done them.

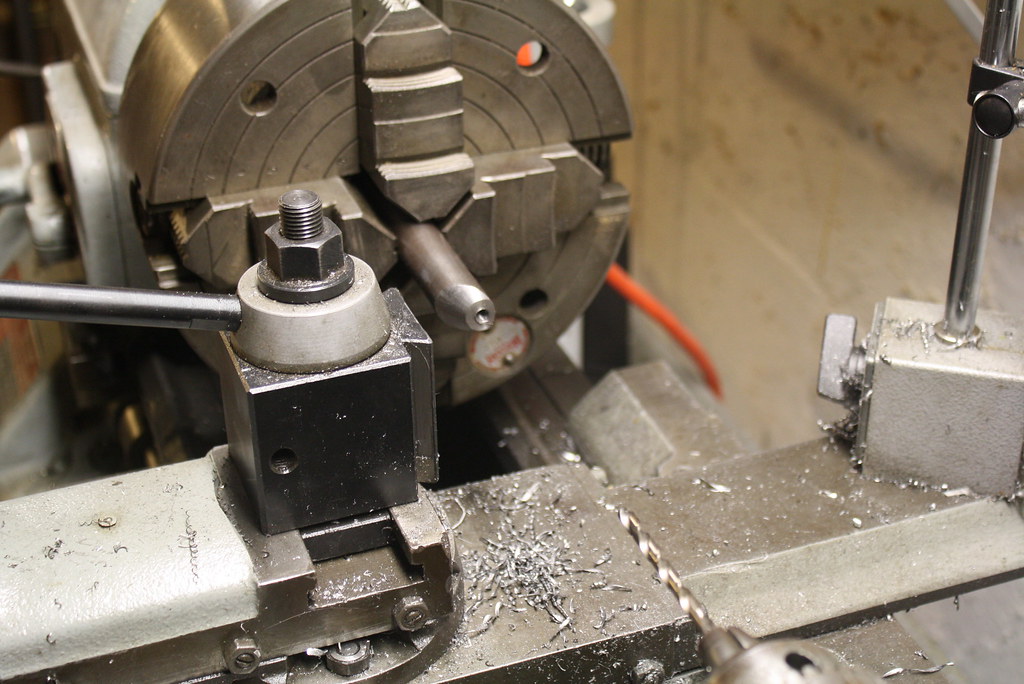

Here's how I made the post mounts for my fat bike fork. I'm wondering if I need to add another gusset between the mounts, any thoughts on that?

-

Re: Fork post mounts

Re: Fork post mounts

I think that looks pretty stout. I'm planning on making a fat fork myself so interested in the comments that follow

cheers

andy walker

Walker Bicycle Company | | Walker Bicycle Company

Flickr: afwalker's Photostream

-

Re: Fork post mounts

Re: Fork post mounts

Belltown Bikes came up with a method that makes mitering a little easier. It's a steel ball that has a flat and M6 hole.

P3231245 | Flickr - Photo Sharing!

These are my direct mounts.

-

Re: Fork post mounts

Re: Fork post mounts

Originally Posted by

Clockwork

Thanks for reminding soft polish steel ball method. That's something I would like to try in the future, should definitely make mitering easier.

-

Re: Fork post mounts

Re: Fork post mounts

Looks nice! I would be tempted to add some support to the bottom mount. Your current set-up would probably suffice just fine. The brake adapter is a gusset in a sense, but a little reinforcement adds extra hours of sleep down the road.

It's kind of funny how post mounts used to be less desirable in the off road past ( for fear of stripping threads), but now it's the new rage.

-Chris

Originally Posted by

J_K

I'm looking ideas for coming forks with the post mounts.

Please show how you have done them.

Here's how I made the post mounts for my fat bike fork. I'm wondering if I need to add another gusset between the mounts, any thoughts on that?

-

Re: Fork post mounts

Re: Fork post mounts

Originally Posted by

Boedie

Looks nice! I would be tempted to add some support to the bottom mount. Your current set-up would probably suffice just fine. The brake adapter is a gusset in a sense, but a little reinforcement adds extra hours of sleep down the road.

It's kind of funny how post mounts used to be less desirable in the off road past ( for fear of stripping threads), but now it's the new rage.

-Chris

I'm still thinking of adding some support to the bottom mount, but I have not made the decision yet. I still have time to think about it before the fork leaves for the paint.

I found this from the Waltworks blog, Waltworks Bicycles: Not weird enough?

Originally Posted by

Waltworks

Actually, if you tie them together, it makes everything much worse - more ways to pull out of alignment. I figure the caliper will be the bridge, so as long as I get the threads where they need to be, it's good to go.

-

Re: Fork post mounts

Re: Fork post mounts

I was thinking about post mounts for a springtime project and after considering the ball-type, I am ordering the post mount made by Paragon. They make one for 135 & another specific to 142 thru axles. Is there anything they make that doesn't look and function well (other than some ugly dropouts)?

-

-

Re: Fork post mounts

Re: Fork post mounts

Originally Posted by

MiWi

Iīm kind of an overcautious guy.

(220lb, even considering my weight, I built myself some probably overdimensioned forks)

You probably donīt need the gussets between the mounts.

Those are my fork-postmounts.

If you haven't painted that move the lower cable guide up the leg a few inches.

Looks good!

- Garro.

-

Re: Fork post mounts

Re: Fork post mounts

Originally Posted by

MiWi

Iīm kind of an overcautious guy.

(220lb, even considering my weight, I built myself some probably overdimensioned forks)

You probably donīt need the gussets between the mounts.

Those are my fork-postmounts.

Those look really good.

I think I will do something similar next time.

What size legs on that fork?

-

Re: Fork post mounts

Re: Fork post mounts

If you haven't painted that move the lower cable guide up the leg a few inches.

For a better lineup with the braking-hose ? The guides fit good imho. I always make a testfit with the brakes, Avid BB7 in this case. No sharp bends, aligned with the hose outlet of the caliper.

Thank you, love to hear that from one of my brazing idols.

What size legs on that fork?

I start with 1.1/8*0.058 seamless aircraft 4130.

Both forkblades get than customized on my lathe.

Left blade is short 0.058 section at the "crown", 0.035 in the middle and 0.040 at the postmount/dropout.

Right blade is short 0.058 section at the "crown", 0.030 in the middle and 0.035 at dropout

"Crown"-Segments are 1.1/8*0.058

"Butting" is done carefully, tubing carefully centered, smooth transitions, complete surface sanded, no scratches or scores.

The "butting" isnīt noticed with the eyes, only when touched.

Michael Wiedemann

Similar Threads

-

By Chauncey Matthews in forum The Frame Forum@VSalon

Replies: 10

Last Post: 09-16-2013, 09:05 PM

-

By dbohemian in forum The Frame Forum@VSalon

Replies: 8

Last Post: 11-17-2012, 10:53 AM

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Originally Posted by Waltworks

Bookmarks