Dear Guest,

Please register or login. Content don't create itself!

Thank you

-

Fabricating my own frame jig - 8020 questions

Fabricating my own frame jig - 8020 questions

Hi,

It's time for me to pull on my big boy pants and have my own jig. Since I don't have an extra couple of grand burning a hole in my pocket, I think I'm going to use 8020 aluminum T-slot for the jig.

I'm thinking about building a "+" shaped jig sort of like this but rather than using cones, I would use blocks that hold each tube; the bottom of the "+" would have a fitting for the BB shell, the top of the "+" would have a frame block (more likely an economy aluminum "V" block from McMaster-Carr) that would be adjustable to hold the top tube, and the horizontal arms of the "+" will have blocks for holding the head tube and seat tube, with the very end of the left arm having a fitting for the rear dropout/stay placement.

My question is this - what are the best T-track types to use for this type of construction? I was thinking that this would work very well, but the solid back would mean that it would be difficult to join the two pieces together for the "+" in a way that would allow the jig to be fully adjustable. I've never used 8020 before, so I might just be missing some basic, but key, concept.

Thanks,

Pete

-

Re: Fabricating my own frame jig - 8020 questions

Re: Fabricating my own frame jig - 8020 questions

I'm pretty sure you want to use one of the symmetric extrusions. The single sided ones are pretty thin. When I made my first jig in the mid '70s, it was pretty common to hold the tubes in a clamp, but for various good reasons that's gone out of style. You're going to have to get cones for the head tube, get another for the seat tube.

I skipped over where you said you were using clamps for the head tube. I think this is not a good idea. The production jigs at Trek when I was there held the head tube by the front. This generally worked ok, but it's not ideal. There are a lot of vintage Treks that are straight only because they had a very long bar to align them with.

-

Re: Fabricating my own frame jig - 8020 questions

Re: Fabricating my own frame jig - 8020 questions

Get larger extrusion. I'd go with at least the 15 series 80/20 (1.5" square) stuff for the seat tube, and the double or bigger for a main beam. Go with stock that has slots on all sides, it'll be way more convenient. Use the same series extrusion for everything, and use double or quad when you need bigger than the single. That way everything will be based off the same dimension. When you join the beams, make sure to use plates on front or back to insure everything stays flat. You can combine and angle piece if you need to keep things square up or down as well.

Alex Whetmore has a couple of cool jigs made from 80/20. His photo site eludes me, but you can check out his blog for tons of good tooling ideas. Alex Wetmore is always busy with something…

I hope this helps, E

-

Re: Fabricating my own frame jig - 8020 questions

Re: Fabricating my own frame jig - 8020 questions

Thanks for the input, guys. Now, the obvious followup question (well, obvious to me)...I don't have a lathe, anyone out there want to fabricate some cones and perhaps a BB holder for me? I think there would be a market for someone taking the well-known Instructables article one step further and selling a "kit" with the parts that you can't get from 8020...maybe even a couple of axle setups.

Thanks again,

Pete

-

Re: Fabricating my own frame jig - 8020 questions

Re: Fabricating my own frame jig - 8020 questions

I've done a small fixture or two with 80/20, it has tons of potential. Somewhere, in another thread Eric E. mentioned that there was another extrusion called 'bosch'. I checked it out and it would deffinately look like a more polished product if you could find some. As for the cones, check ebay, before the chopper building crash there was a guy selling cones to make a motorcycle frame jig out of. I had to look myself; FRAME JIG CENTERING CONES: eBay Motors (item 230532662870 end time Oct-07-10 13:52:08 PDT) . for thirty five dollars plus shipping you arent going to find anyone to make you any, you might get him to combine shipping for two sets (BB+ HT).

another route for cones is an Ironworker supply shop. There is a tool they use when assembling structural steel, its two cones connected by a piece of acme rod with the rod fixed in one side, it is used as a temp bolt on the plates or beams with mulitple holes to align the plates as they bolt up. I used one for an alignment fixture, If I get time i wil post a picture.

keep us posted!

-

Re: Fabricating my own frame jig - 8020 questions

Re: Fabricating my own frame jig - 8020 questions

Bellman - those look like they would be perfect! Thanks!

I will try to document the process, take feedback for improvements, etc., in the hopes that the results would be an "open source" framebuilding jig that will be just fine for 90% of low-production builders, and made from commercially available products wherever possible. As a new (but enthusiastic, and I think I have good potential) builder, the most frustrating thing about framebuilding is the expense. I could easily spend $4k on a basic, ready-made frame jig, fork jig, blade raking fixture, and torch setup, and that's one hell of a lot of money.

Thanks for the help and interest,

Pete

-

Re: Fabricating my own frame jig - 8020 questions

Re: Fabricating my own frame jig - 8020 questions

do you have an alignment table? If not, get that first. It'll reveal so much to you about your procedure and can do everything a fixture can do.

-

Re: Fabricating my own frame jig - 8020 questions

Re: Fabricating my own frame jig - 8020 questions

Originally Posted by

cement shoes

do you have an alignment table? If not, get that first. It'll reveal so much to you about your procedure and can do everything a fixture can do.

I was thinking of approximating one with 4-5 layers of MDF screwed and glued together, them checked with a straightedge. I know it's not the same thing, but it'd be better than nothing...again, the cost of buying one is high, and they don't come up on my local CL very often.

Pete

-

Re: Fabricating my own frame jig - 8020 questions

Re: Fabricating my own frame jig - 8020 questions

Originally Posted by

cement shoes

do you have an alignment table? If not, get that first. It'll reveal so much to you about your procedure and can do everything a fixture can do.

I 2nd that. rutland tool is selling 36" x 48" x 6" black granite plates cert to .0002" for $900.00 off right now - $299.00! the thing is that it's 1,325lbs....{ mod# 9000 1467t} ..i'd like one just to roll tubes on if i could do a pick-up on it. shipping would be mucho dinero - Garro.

Last edited by steve garro; 10-06-2010 at 02:38 PM.

-

Re: Fabricating my own frame jig - 8020 questions

Re: Fabricating my own frame jig - 8020 questions

Last edited by jerk; 10-06-2010 at 02:51 PM.

-

Re: Fabricating my own frame jig - 8020 questions

Re: Fabricating my own frame jig - 8020 questions

Originally Posted by

pruckelshaus

Bellman - those look like they would be perfect! Thanks!

I could easily spend $4k on a basic, ready-made frame jig, fork jig, blade raking fixture, and torch setup, and that's one hell of a lot of money.

Thanks for the help and interest,

Pete

\

no it's not. buy one. don't use mickey mouse tools if you don't want to build a mickey mouse house.

-

Re: Fabricating my own frame jig - 8020 questions

Re: Fabricating my own frame jig - 8020 questions

Originally Posted by

pruckelshaus

4-5 layers of MDF screwed and glued together, them checked with a straightedge. I know it's not the same thing, but it'd be better than nothing

I wouldn't hold my breath on this one. The wood industry pays my mortgage, but I wouldn't trust them to inspect my frames.

Where do you live? I can keep an eye open for you.

Tony

Anthony Maietta

Web Site |

Blog |

Flickr

"The person who says it can not be done, should not interrupt the person doing it."

-

Re: Fabricating my own frame jig - 8020 questions

Re: Fabricating my own frame jig - 8020 questions

I looked at 8020 type extrusions initially but found them to be expensive for what I wanted. Having access to a mill helped when I decided to make my own. If you do use 8020 check for straightness and or twist. You may need to shim things to get them true. Watch any machining on the faces, if not done equally on both side they may pull on you. I used 1x2" solid 6061-T6 and faced both sides for flatness

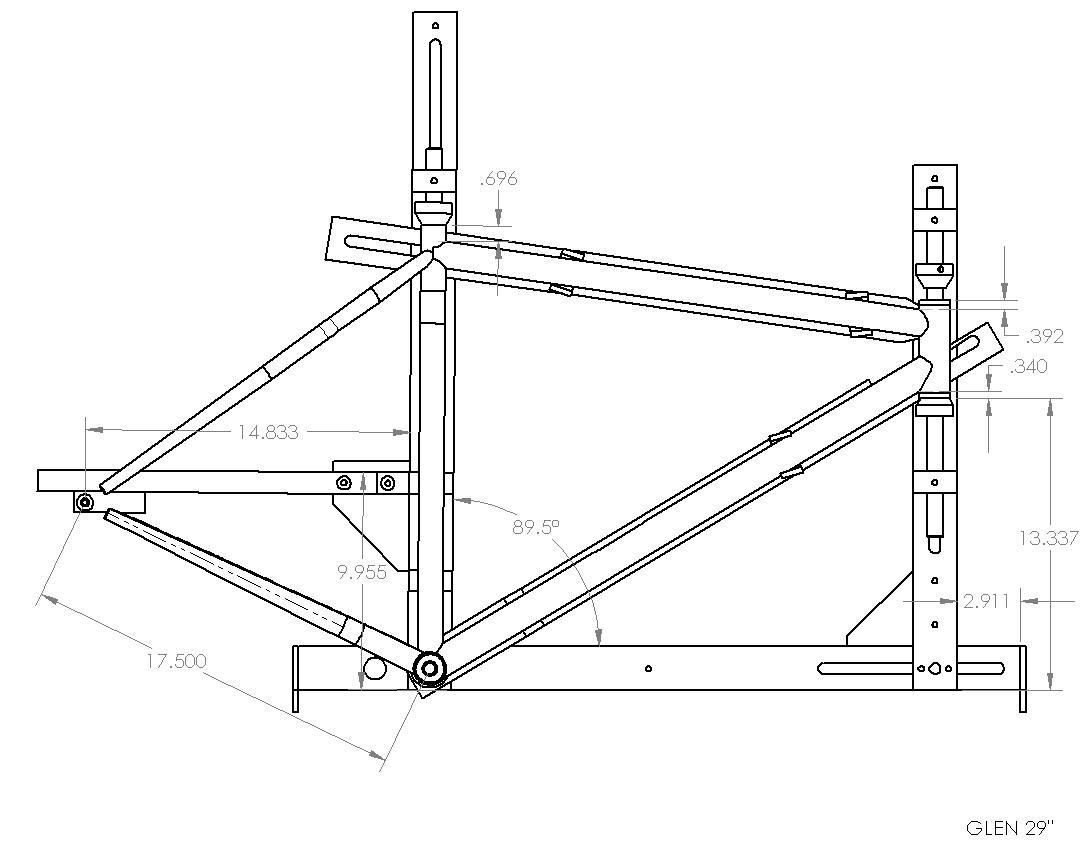

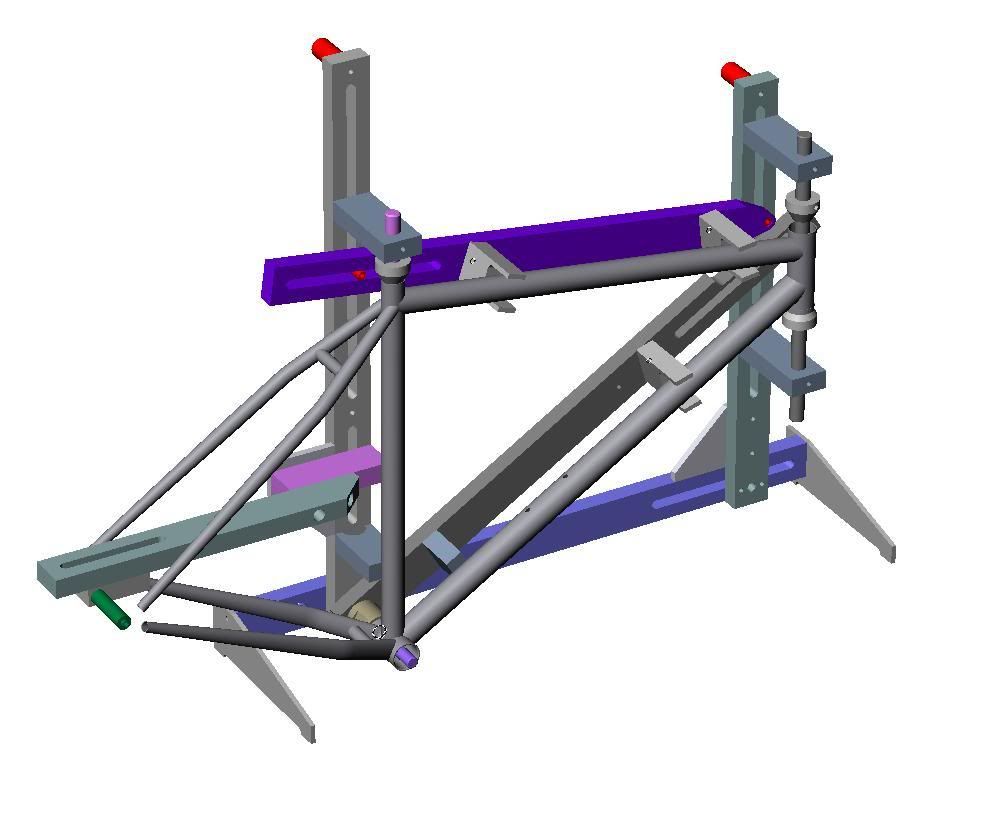

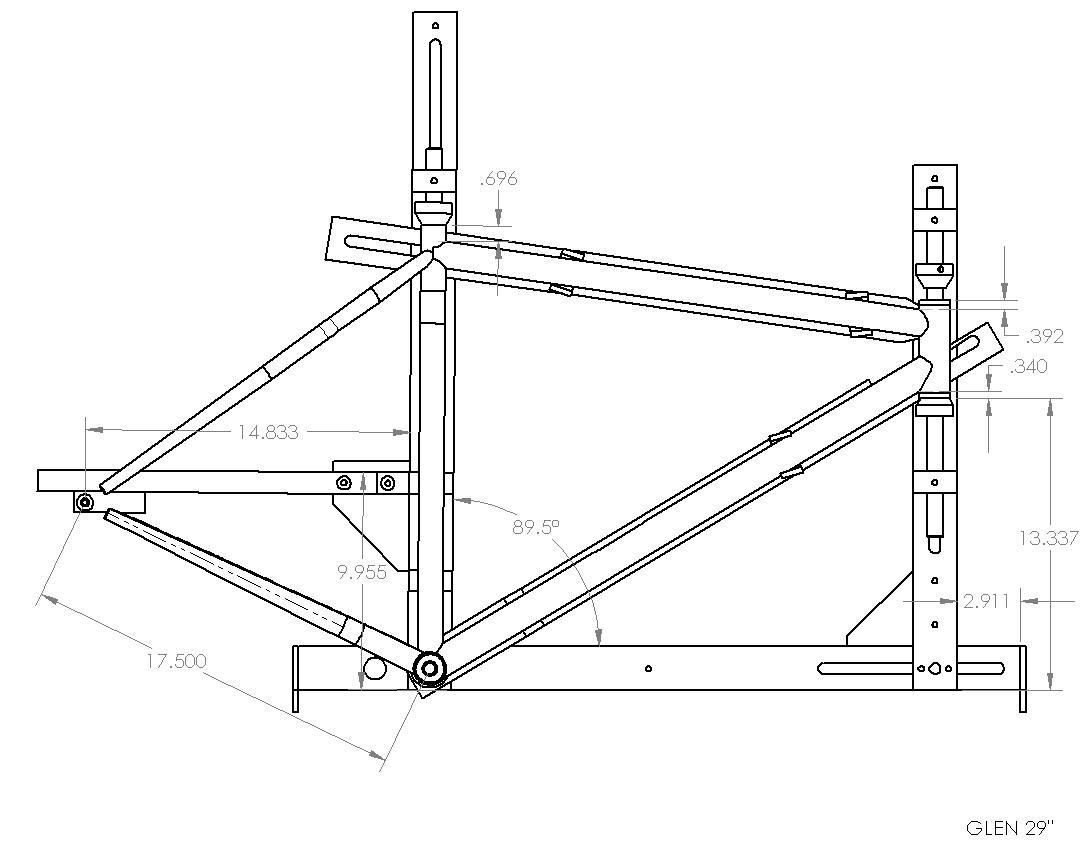

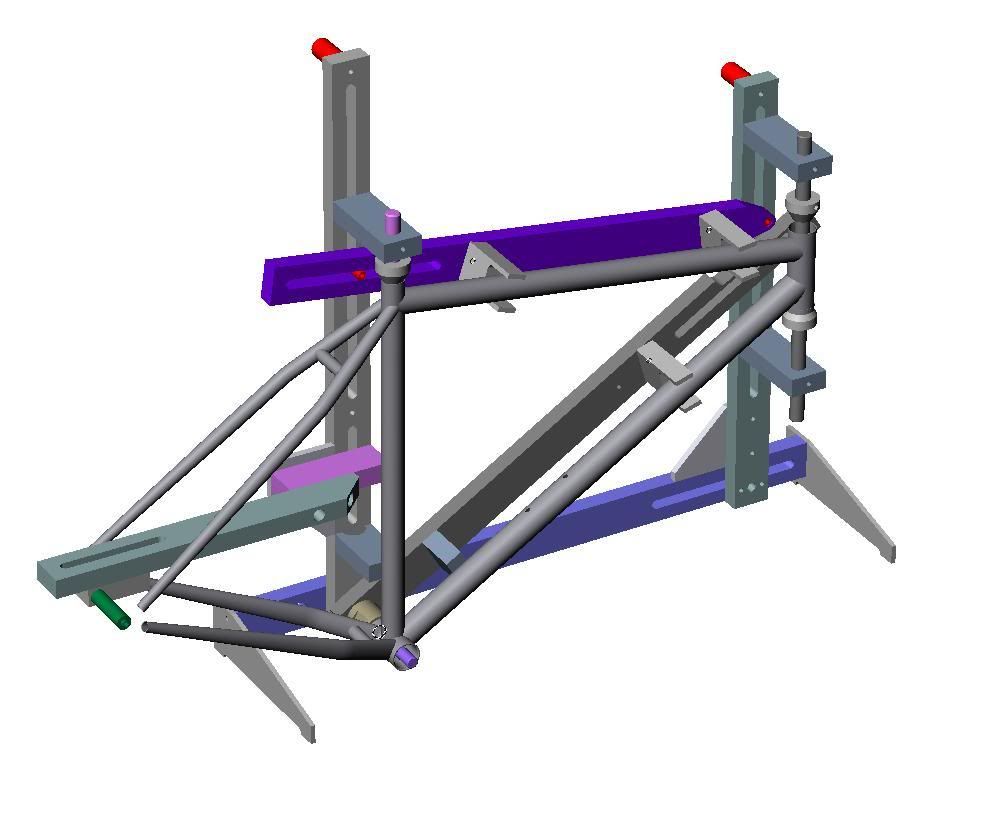

I modeled it in CAD and it ended up being pretty easy to set up. The head tube is held on cones, the BB on a face and a cone and the miters determine the top and down tube position.

-

Re: Fabricating my own frame jig - 8020 questions

Re: Fabricating my own frame jig - 8020 questions

I would think a craigslist cast iron table saw could be had for nearly the same price as 4 or 5 layers of mdf, would be far more accurate and you could braze on it if you like. Not to mention the resale value......and it would double as a table saw..................somebody make me stop. :-)

-

Re: Fabricating my own frame jig - 8020 questions

Re: Fabricating my own frame jig - 8020 questions

if you're serious about building, don't do MDF. You can find a used cast iron plate or granite for under $500.00. I think Bringheli's large table and accessories is something like 2K and his c-channel set up is under a grand. He will also sell you just the accessories if you ask him. Brett Flemming out at EVT will make you a bb post for whatever table you have. If you have the table, you can then use things like angle plates, v-blocks, a good square, height guage, etc. to do a surprising amount of set ups and checks. For example, I use my table, v-blocks and a square to set up capped seat stays in a pair of v-blocks so the slot will be machined parallel to the caps.

-

Re: Fabricating my own frame jig - 8020 questions

Re: Fabricating my own frame jig - 8020 questions

I built my first ~ 40 frames on this: metalwork+2008+643.jpg (image) made by Jim Stein in the 70's. it made straight front triangles, but the set-up for the rear was wonky at best. it used the angle of the ST/CS to set up, which sucks, believe me. - Garro. EDIT: the fork jig in the pic WAS sweet! i was bummed to see it go.

Last edited by steve garro; 10-06-2010 at 03:18 PM.

-

Re: Fabricating my own frame jig - 8020 questions

Re: Fabricating my own frame jig - 8020 questions

Ideas

Table first- it's relativly easy to set up on a table for tacking, and good to use for inspection long term. As has been mentioned- jigs help to make things faster (maybe), but not necissarily straighter if the tool is off. The table is a great long term investment.

The Sputnik uses a section of Bosch- similar to 80-20.

-

Re: Fabricating my own frame jig - 8020 questions

Re: Fabricating my own frame jig - 8020 questions

Originally Posted by

steve garro

I built my first ~ 40 frames on this:

metalwork+2008+643.jpg (image) made by Jim Stein in the 70's. it made straight front triangles, but the set-up for the rear was wonky at best. it used the angle of the ST/CS to set up, which sucks, believe me. - Garro. EDIT: the fork jig in the pic WAS sweet! i was bummed to see it go.

Crap, Steve! I remember a motorcycle shop that had frame fixtures that size.

-

Re: Fabricating my own frame jig - 8020 questions

Re: Fabricating my own frame jig - 8020 questions

OK, I'll keep my eye out on Craig's List for something 36x36 or larger. I assume I would then need to have it bored out for a BB post.

-

Re: Fabricating my own frame jig - 8020 questions

Re: Fabricating my own frame jig - 8020 questions

Originally Posted by

pruckelshaus

OK, I'll keep my eye out on Craig's List for something 36x36 or larger. I assume I would then need to have it bored out for a BB post.

you didn't catch this post? - I 2nd that. rutland tool is selling 36" x 48" x 6" black granite plates cert to .0002" for $900.00 off right now - $299.00! the thing is that it's 1,325lbs....{ mod# 9000 1467t} ..i'd like one just to roll tubes on if i could do a pick-up on it. shipping would be mucho dinero - Garro.

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Likes:

Likes:

Reply With Quote

Reply With Quote

Bookmarks