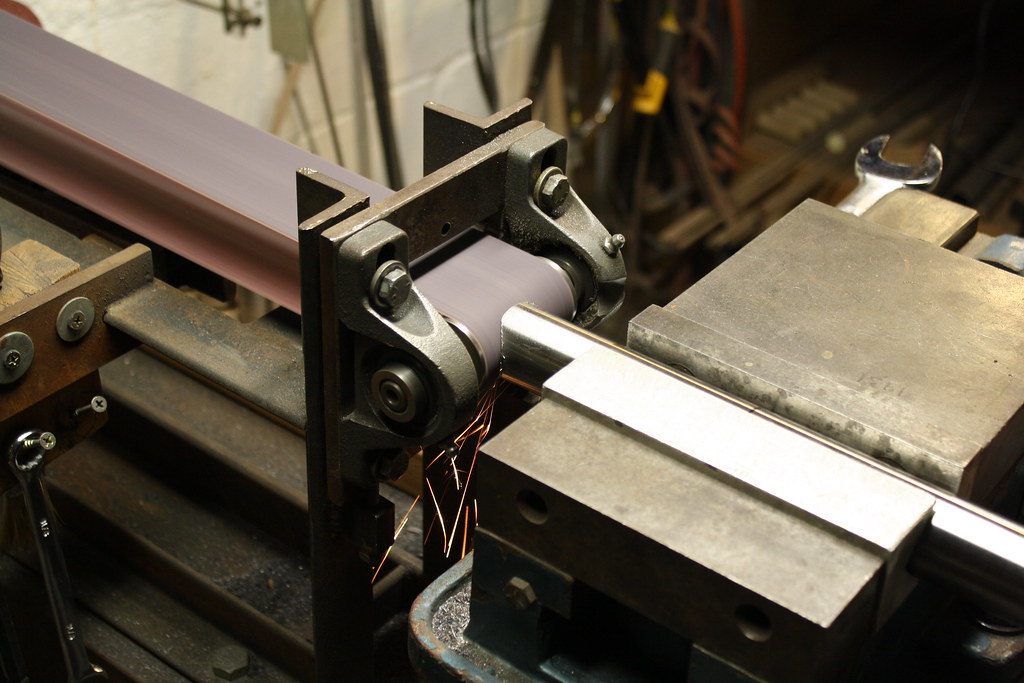

Abrasive coping.....I'm considering trying to set-up an abrasive coping rig, and am curious what pitfalls I should avoid. I know some are successfully doing this. There appears to be a few commercial set-ups that can be used, or modified to work well, but they seem costly and excessive. Not that I'm trying to keep it cheap, but I'd like to keep the scope of the project reasonable for bicycle tubing.

Some of the "pros" I see are cheaper belts, cleaner cuts, better on thin metal, and speed. Also, smaller footprint than a mill AND you can still use it as a belt sander.

The only "con" I can think of is more dust/air particulates.

Has anyone tried both and prefer one way over the other?

Any input would be appreciated. Thanks!

Likes:

Likes:

Reply With Quote

Reply With Quote

Bookmarks