Dear Guest,

Please register or login. Content don't create itself!

Thank you

-

-

Re: Anvil Bikes

Re: Anvil Bikes

Hey Don,

Couple of technical questions...

Who's linear slides are you using? Thompson, Bosch, THK? I've been sourcing Bosch thru Northwest Motion but would consider some alternatives. Also, the engraving on your tools is tits. Are you using a 2 flute 90 deg carbide chamfer mill? Maybe my feedrates are too high (10,000 rpm @ 25 ipm) The tip doesn't last long in the anodized stuff.

D

-

Re: Anvil Bikes

Re: Anvil Bikes

Originally Posted by

drewgh2o

Hey Don,

Couple of technical questions...

Who's linear slides are you using? Thompson, Bosch, THK? I've been sourcing Bosch thru Northwest Motion but would consider some alternatives. Also, the engraving on your tools is tits. Are you using a 2 flute 90 deg carbide chamfer mill? Maybe my feedrates are too high (10,000 rpm @ 25 ipm) The tip doesn't last long in the anodized stuff.

D

Yo Drew, I've used both Thompson and THK. Mostly THK because my local distributor is a cyclist and a bud. They're really overkill on frame fixtures though.

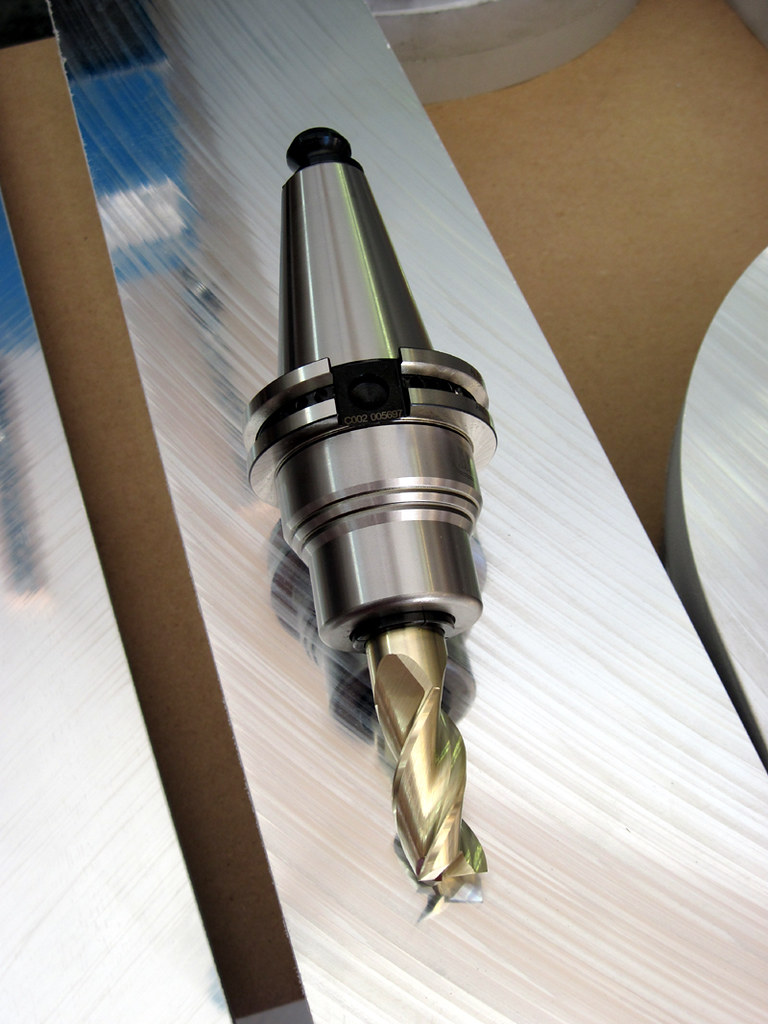

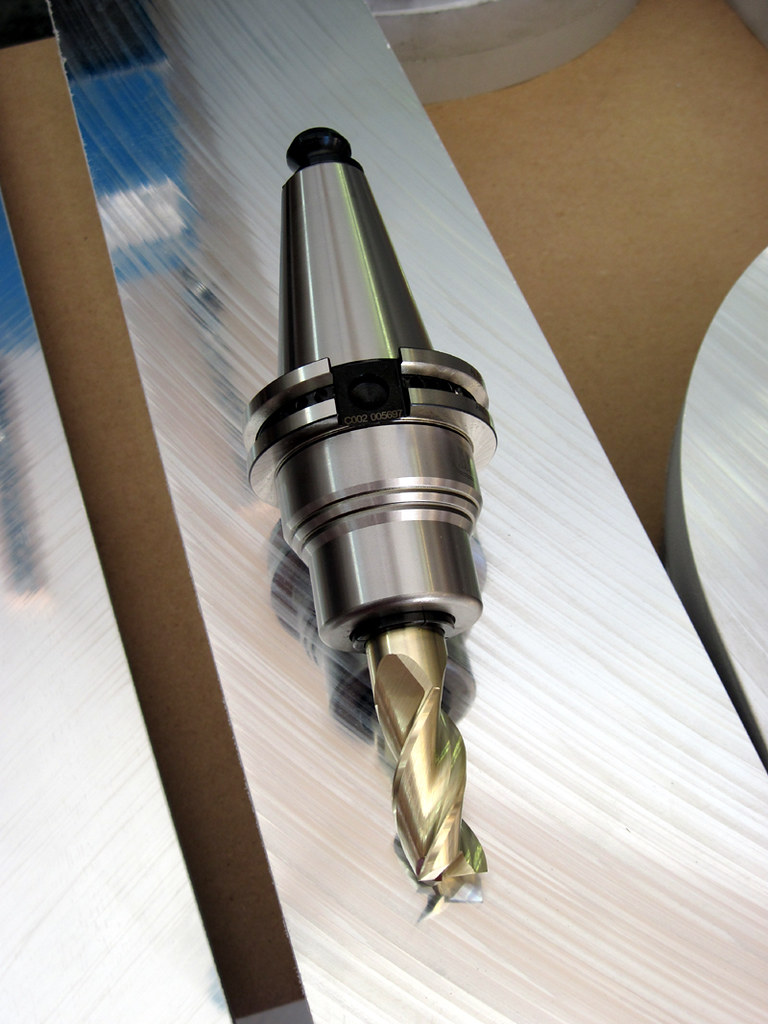

I went through hell getting the engraving squared away. As you know, hardcoat has a Rockwell hardness of about 70-80C and so it eats cutters left and right. Plus it likes to flake if your cutter gets dull. For a long time we were using Micro100, 60-degree, single flute, double end, 1/8" engraving cutters. Decent results when new, but not much life and when it started to go south, you pretty much lost that part. Our MSC rep brought the OSG rep over and we went through the problems we were having and he recommended we try one of their miniature, .03125" 4-flute ball end carbide cutters with their then new WSX coating. Damn! We started saying those cutters were made out of Jesus metal. They last about 100 times longer than the Micro's at better speeds & feeds and I'm not kidding in the least. The only real drawback to using a ball end is that they're a lot more sensitive to surface variations where a .001" different in surface can make a big difference in the width of the cut.

"It's better to not know so much than to know so many things that ain't so." -- Josh Billings, 1885

A man with any character at all must have enemies and places he is not welcome—in the end we are not only defined by our friends, but also those aligned against us.

-

Re: Anvil Bikes

Re: Anvil Bikes

Yo Drew, I've used both Thompson and THK. Mostly THK because my local distributor is a cyclist and a bud. They're really overkill on frame fixtures though.

I went through hell getting the engraving squared away. As you know, hardcoat has a Rockwell hardness of about 70-80C and so it eats cutters left and right. Plus it likes to flake if your cutter gets dull. For a long time we were using Micro100, 60-degree, single flute, double end, 1/8" engraving cutters. Decent results when new, but not much life and when it started to go south, you pretty much lost that part. Our MSC rep brought the OSG rep over and we went through the problems we were having and he recommended we try one of their miniature, .03125" 4-flute ball end carbide cutters with their then new WSX coating. Damn! We started saying those cutters were made out of Jesus metal. They last about 100 times longer than the Micro's at better speeds & feeds and I'm not kidding in the least. The only real drawback to using a ball end is that they're a lot more sensitive to surface variations where a .001" different in surface can make a big difference in the width of the cut.

You say "overkill" I say "why not?" Ha ha. One of my customers designs their own XY stages is why I ask. Ahhh MSC, where would we be without them. Thanks for the "tip" on OSG ballmill. Of course, it's a die/mold tool! Jesus metal, nice. I'll start shopping that one around. Unfortunately, the ultra-classy look of anodized parts with engraving has caused me to throw away waaay too many chamfer mills. Noted on the depth of cut.

-

-

Re: Anvil Bikes

Re: Anvil Bikes

Don,

I'm feeling your satisfaction with the cart o' parts. I loves me them short run production. Hey, couple more questions: What kind of coolant are you using, is a BLACK Notorious B.B.G. a possibility if I'm not in a hurry, are the Albrecht toolholders worth the jack?

D

-

Re: Anvil Bikes

Re: Anvil Bikes

Originally Posted by

drewgh2o

Don,

I'm feeling your satisfaction with the cart o' parts. I loves me them short run production. Hey, couple more questions: What kind of coolant are you using, is a BLACK Notorious B.B.G. a possibility if I'm not in a hurry, are the Albrecht toolholders worth the jack?

D

You gotta' know when to hold them and know when to fold them. Is Kenny Rogers dead yet?

Coolant of choice around here is Rustlik 500 for most stuff & Rustlik 50/50 if we're lots of stainless. We've tried lots of different types and brands, some work just as good but we can't stand the smell, or it makes our eyes water, or causes skin sensitivity, so we always come back to 500. I'll probably never change at this point, but if some new wonder coolant comes out, we'll give it a shot. What are you running?

Yes, the Albrecht's are all that. I think we have a dozen of them now and we're really impressed with them. A little pricey, but not bad compared to other milling chucks. I'll be buying more.

Last edited by Archibald; 12-03-2010 at 02:11 PM.

Reason: "Rustlik" not "Rustlick"

"It's better to not know so much than to know so many things that ain't so." -- Josh Billings, 1885

A man with any character at all must have enemies and places he is not welcome—in the end we are not only defined by our friends, but also those aligned against us.

-

Re: Anvil Bikes

Re: Anvil Bikes

Coolant of choice around here is Rustlik 500 for most stuff & Rustlik 50/50 if we're lots of stainless. We've tried lots of different types and brands, some work just as good but we can't stand the smell, or it makes our eyes water, or causes skin sensitivity, so we always come back to 500. I'll probably never change at this point, but if some new wonder coolant comes out, we'll give it a shot. What are you running?

On the advice of the tech who installed the machine, I've been a Blaser Universal 2000 guy. He said it was friendlier to the seals in the column. It would be OK for a few months but when it went bad, it really went. Adding odor tablets only seemed to make the coolant more prone to rusting the vises if they weren't completely blown dry at night. This last go round I cleaned everything, started with fresh coolant and put one odor tablet in the sump to start things off. I have hydronic heat in the floor which keeps the coolant warmer than I'd like in the winter but it seems to be stable for going on 2 months now.

I think Kenny's still kickin' BTW.

-

Re: Anvil Bikes

Re: Anvil Bikes

The M6 threads on my/your Feng Shui appear to be tapped offline using a Procunier or some such (different depths, cut threads). Does the Hurco have rigid tapping and if it does are you using roll taps now? I like the Balax Thredfloer products FWIW. Also, why is the shank on a 1/2-13 tap smaller than the shank on a 3/8-16 tap?

-

Re: Anvil Bikes

Re: Anvil Bikes

Originally Posted by

drewgh2o

The M6 threads on my/your Feng Shui appear to be tapped offline using a Procunier or some such (different depths, cut threads). Does the Hurco have rigid tapping and if it does are you using roll taps now? I like the Balax Thredfloer products FWIW. Also, why is the shank on a 1/2-13 tap smaller than the shank on a 3/8-16 tap?

Yeah, the Hurco has rigid tapping but we do almost all tapping with a ShopTap & Bilz adapters. It's just faster. For the stuff I use, 1/2 is the same shank as 3/8. Whose is smaller?

"It's better to not know so much than to know so many things that ain't so." -- Josh Billings, 1885

A man with any character at all must have enemies and places he is not welcome—in the end we are not only defined by our friends, but also those aligned against us.

-

Re: Anvil Bikes

Re: Anvil Bikes

Originally Posted by

Wayne Lim

Don,

PS: Kevin Grady, if you're reading this, give me a shout at any of the old contacts you had for me. We've got to get a reunion going. . .

Hey, Wayne, I was down in your neighborhood, across from the new Fed Courthouse, I should have dropped in but I was shy of running into the full body scan :-) Yea, I need to contact Rich and we can at least start with some mahogany miles tipping a few brews.

I did not know about Jimbo, either, I need to make my condolences over at the TTF. Wayne, don't be a stranger, here, and now we also have DWF here to spice things up. Have not heard a good part breaking story in a long time.

Kevin Grady

-

Re: Anvil Bikes

Re: Anvil Bikes

Yeah, the Hurco has rigid tapping but we do almost all tapping with a ShopTap & Bilz adapters. It's just faster. For the stuff I use, 1/2 is the same shank as 3/8. Whose is smaller?

I use ER 32 tap collets which have a square feature EDM'd in them to keep the tap from slipping in the collet. The collets for 1/2" taps have a .367 bore and the collets for 3/8" taps have .381 bore.

ER-TC Rigid Tap Collets

Just thought it was strange that 3/8" got the beefy shank...

-

Re: Anvil Bikes

Re: Anvil Bikes

Hey Don, the Dr. Who prop manager called, said he wanted his robot back! Gawd, I love that diamond plate. Muy Macho!

-

Re: Anvil Bikes

Re: Anvil Bikes

Originally Posted by

Gradient

Hey Don, the

Dr. Who prop manager called, said he wanted his robot back! Gawd, I love that diamond plate. Muy Macho!

Ha! The JMan sat on that stand because I hadn't yet figured out how to balance it and have it pivot like the Masters without the (super expensive) trunnions we were using on them back then. Still have parts of display that kicking around and I scavenged the diamond plate to use on our new fold up booth which you can kind of see in the background here:

"It's better to not know so much than to know so many things that ain't so." -- Josh Billings, 1885

A man with any character at all must have enemies and places he is not welcome—in the end we are not only defined by our friends, but also those aligned against us.

-

Re: Anvil Bikes

Re: Anvil Bikes

A good welding exercise I tell folks and what we used to do in my pipe-welding days was to take a tig torch and walk the cup around the OD of a beer bottle. You'll be surprised how hard this is. You're not actually welding, you're just practicing the motions so the machine is not turned on, the tig torch doesn't have to be connected to anything and you can do it in the comfort your home or local tavern. Take the label off the bottle, and hold it in one hand so its length is parallel to the ground. Hold your torch in the other. Place your tig torch's cup against the side of the bottle and rock the torch between your fingers so that you're making the cup advance along the bottle in a small figure 8 motion. Do not let the tungsten touch the bottle. Try to maintain relative perpendicularity between your tungsten and the bottle as you advance around the OD of the bottle. When you can make it 180-degrees around the bottle without the torch slipping off or sliding away on the bottle you have become better than 99% of the folks out there.

I'm not quite getting the whole "torch cup on the side of the bottle" thing if I'm suposed to maintain perpendicularity with the workpiece. More importantly, I realised the other day that I might 180 degrees off in my approach to front triangle joints as a whole. I have been welding joints with the mitered tubes pointing away from me, essentially I'm welding the joint clockwise (I'm holding the torch in my right hand) and it occurred to me that perhaps I should be using the mitered tube as a torch guide, letting the diameter of the mitered tube act as my torch hand support. Hey, I only have 8-10 stops and starts per joint! I've spent most of my time learning TIG welding on HT joints because they're large dia but as I get into the rear triangle stuff (DO's, CS bridge, ST/SS) would the same logic hold true? Should a right handed welder be welding ALL joints counter-clockwise with the mitered tube pointing toward them? And lastly, could you talk a little about torch electrode motion throughout a pass. I like to start a pass right on the tack with the pedal to the metal and then get some filler in there get the puddle going. Sometimes/always it requires some fancy maneuvers on the torch side of things to get the puddle nicely balanced between the tubes and flowing evenly. Then as I start laying down the beads I find myself lifting the electrode up and back so I can stab the filler into the front of the puddle and also see WTF is happening at the back of the puddle, then getting the filler out of the way so I can lower the electrode and advance the puddle. You mention figure 8's. Is that simply a practice motion or are you weaving the electrode throughout the pass. Note: I'm using a pre-war Linclon Idealarc with no pulse and a water cooled CK 20 series torch head. 3/32 electrode and .035 dia. 312 SS filler.

Thanks again,

D

-

Re: Anvil Bikes

Re: Anvil Bikes

Originally Posted by

drewgh2o

I'm not quite getting the whole "torch cup on the side of the bottle" thing if I'm suposed to maintain perpendicularity with the workpiece. More importantly, I realised the other day that I might 180 degrees off in my approach to front triangle joints as a whole. I have been welding joints with the mitered tubes pointing away from me, essentially I'm welding the joint clockwise (I'm holding the torch in my right hand) and it occurred to me that perhaps I should be using the mitered tube as a torch guide, letting the diameter of the mitered tube act as my torch hand support. Hey, I only have 8-10 stops and starts per joint! I've spent most of my time learning TIG welding on HT joints because they're large dia but as I get into the rear triangle stuff (DO's, CS bridge, ST/SS) would the same logic hold true? Should a right handed welder be welding ALL joints counter-clockwise with the mitered tube pointing toward them? And lastly, could you talk a little about torch electrode motion throughout a pass. I like to start a pass right on the tack with the pedal to the metal and then get some filler in there get the puddle going. Sometimes/always it requires some fancy maneuvers on the torch side of things to get the puddle nicely balanced between the tubes and flowing evenly. Then as I start laying down the beads I find myself lifting the electrode up and back so I can stab the filler into the front of the puddle and also see WTF is happening at the back of the puddle, then getting the filler out of the way so I can lower the electrode and advance the puddle. You mention figure 8's. Is that simply a practice motion or are you weaving the electrode throughout the pass. Note: I'm using a pre-war Linclon Idealarc with no pulse and a water cooled CK 20 series torch head. 3/32 electrode and .035 dia. 312 SS filler.

Thanks again,

D

If you're holding the torch in your right hand and your progression is clockwise, you are welding backwards. You'd want to weld counter clockwise as you deduced. Feed the filler to the front of the tungsten/puddle. Perpendicularity is relative, you want the tungsten pointed slightly in the direction of travel so you're rarely at perfect 90-degrees to the workpiece but you don't want to form obtuse or acute angles either. I always bias my heat towards the thicker parent metal so you'd point your tungsten slightly in that direction or just off the edge of the intersecting tube so you don't burn the edge back.

As far as tungsten motion on bike tubes, just progression is all that's needed, figure 8s and whatnot are used on thicker materials (the use of figure 8's on the slippery ass beer bottle is to teach you fine motor control and develop your muscle memory and those are critical to laying down the good shit). You don't want to start adding filler on a tack. You can start on a tack but then move backwards off the tack, add filler to match, then when you progress back over the tack and remelt it, only add filler to maintain your bead size. If you start on the tack and add filler you get a lump and will quite possible have a void under it since tacks are rarely hot enough. When I tack I add minimal filler, just a dab and depending on what I'm doing, I'll just fuse them with no filler at all. I don't tack much either. I used to tack on quads or in three places, but now I just tack on centerline, top and bottom. With Tig the miter is CRITICAL. Anywhere you have a gap or an imprecise fit, the filler metal will pull to close the joint and that causes alignment issues down the road.

Pre-war Ideal Arc. You mean Pre-war like WW2? That's hardcore!

Last edited by Archibald; 12-05-2010 at 11:40 AM.

"It's better to not know so much than to know so many things that ain't so." -- Josh Billings, 1885

A man with any character at all must have enemies and places he is not welcome—in the end we are not only defined by our friends, but also those aligned against us.

-

Re: Anvil Bikes

Re: Anvil Bikes

Originally Posted by

drewgh2o

On the advice of the tech who installed the machine, I've been a Blaser Universal 2000 guy. He said it was friendlier to the seals in the column. It would be OK for a few months but when it went bad, it really went. Adding odor tablets only seemed to make the coolant more prone to rusting the vises if they weren't completely blown dry at night. This last go round I cleaned everything, started with fresh coolant and put one odor tablet in the sump to start things off. I have hydronic heat in the floor which keeps the coolant warmer than I'd like in the winter but it seems to be stable for going on 2 months now.

I think Kenny's still kickin' BTW.

I've been using Rustlick 500 for YEARS and it's never gone bad on us and we don't use any additives. Gotta' keep the oil out of it, because in my experience, it's the way oil that causes all the problems.

"It's better to not know so much than to know so many things that ain't so." -- Josh Billings, 1885

A man with any character at all must have enemies and places he is not welcome—in the end we are not only defined by our friends, but also those aligned against us.

-

Re: Anvil Bikes

Re: Anvil Bikes

It's Sunday & time for a diversion. I love shit like this and that will tell you more about me than pages of autobiographical boredom:

So what do you get when you cross Nirvana, ukuleles, and a singer who sounds like Count Chocula? The Ukulele Orchestra of Great Britain covering Nirvana's "Smells like Teen Spirit." I dare you not to enjoy this! Happy Sunday!

Smells like Teen Spirit - The Ukulele Orchestra

"It's better to not know so much than to know so many things that ain't so." -- Josh Billings, 1885

A man with any character at all must have enemies and places he is not welcome—in the end we are not only defined by our friends, but also those aligned against us.

-

Re: Anvil Bikes

Re: Anvil Bikes

not to hijack but you may like this?

-

Re: Anvil Bikes

Re: Anvil Bikes

Originally Posted by

3wfab

not to hijack but you may like this?

ATHF, baby!

Master Shake rocks.

This makes me LOL, too:

"It's better to not know so much than to know so many things that ain't so." -- Josh Billings, 1885

A man with any character at all must have enemies and places he is not welcome—in the end we are not only defined by our friends, but also those aligned against us.

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Bookmarks