At about the age of 7, I rode my first bike. It was my sisters Schwinn, and because of its Ďgirlsí frame, I could straddle it while standing and peddling. By the age of 9 I had my own full size Schwinn, a Typhoon in red. For me the bike was my car Ė offering a measure of freedom.

Naturally my bike provided a quick means of visiting friends, running errands, or getting to school. For 8-9 months of the year, it also provided me with an escape from home life. As an escape, I was in no hurry to return. Because I rarely had a destination, that meant riding farther and farther.

By then, I met a new friend, someone with older brothers. The oldest of them were attending the U (University of Minnesota), conferring on them a major coolness factor. Naturally my buddy liked to ride, but when his brothers discovered fine European bikes, our interest in bikes and riding grew exponentially.

John worked and saved his money for a used, basic, Gitane. My father didnít believe in all that flimsy junk from overseas, nor in the uncomfortable skinny saddles or downturned handlebars. So my savings were directed into a Schwinn w/ a five-speed Huret Allvit setup. Sprung vinyl seat, chromed upright bars, heavy steel frame and wheels. It wasnít sexy, but I had gears and could cover more ground.

A few years later, I entered High-School (outside of Chicago). By then, the seeds of the bike boom were planted, and my savings were focused on a Peugeot PX-10. My father drove me the hour-and-half down to Chicago and a real bike shop. My first reaction on seeing the bike, with its flat tubulars, was that something must be wrong. Naturally, my father remarked about the tires and everything else about this crazy, expensive, bike. All of which convinced me that the PX-10 was perfect.

I had a lot to learn about bike maintenance and repair. Like the time I rolled a front tire and ended up on my back, still clipped to the pedals w/ hands on the brake hoods, with the bike pointing up into the air. There werenít any shops closer than 30 minutes away (by car) from our house. And even these didnít cater to higher-end equipment. There was, however, a shop in Minneapolis with a mail-order catalog Ė I donít remember the name - which carried everything I needed and wanted. Most of the catalog seemed to be illustrated by D. Rebour, and I studied it cover to cover for every clue I could find Ė as I steadily developed my mechanical skills.

More importantly I rode. Compared to the Schwinn, this bike felt like it floating on clouds. Just coasting was a magical experience. The fit, however, never felt right to me. So in college, I sold it and bought a Bob Jackson Ė mustard yellow with a black head-tube and seat panel Ė that I used to explore the countryside.

About then, I ran across the Proteus Framebuilding Handbook at the Student Bookstore. Looking at the book now, explains the process of how to build a frame. But at the time, it struck me as sketchy and seemed to gloss over important details of brazing.

In fact, I made the wise choice not to build a frame with only the Handbook as my guide. But the desire to build a frames was lit and would continue burning for many years to come.

I believe that some folks are more creative than others. Not that they are better, or more clever, rather some folks have more of a need to create. And this need can be addressed in many ways Ė not necessarily by what we normally would consider arts or crafts. I am someone who needs a creative outlet. Part of what I enjoy is problem solving. I also have a clearly logical side to my thinking, which questions much and demands good answers (at least according to my terms).

Some years ago, after surviving more than 15 M&As (the count was lost somewhere after that), I was downsized during an acquisition. This was near the beginning of the Internet economic slump, and for the IT industry, this was exacerbated by the completion of Y2K projects. For two years I had good success in the recruiting process, without making it past the brides-maid stage. At about the same time, I turned 50. This seems to be a combination of magic numbers Ė because suddenly phone calls were no longer returned by headhunters and hiring organizations.

So, with family obligation, I turned to other employment which paid bills Ė even if it didnít satisfy my creativity and problem solving Jones.

Magically, in this period, I stumbled across some evolving resources where frame-builders Ė really big name people Ė were beginning to use the Internet to share knowledge of the process of frame-building. There were a number of antecedents to this, including the publishing of several books more comprehensive than Proteus, and certain frame-builders offering courses for hire on how to build a frame. Today we see the results of this mass of interest and knowledge-sharing which has reached a sustainable boil.

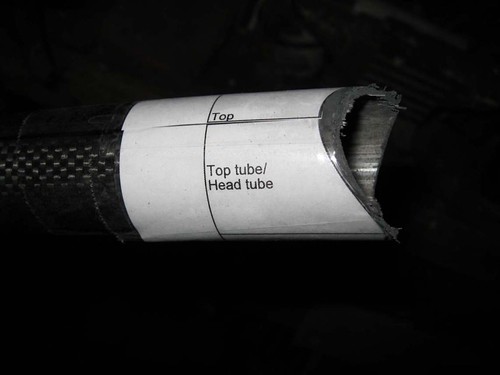

Iíve been learning to build bikes now for about 6-7 years - yet Iím probably the worldís slowest builder. Iím different from many because I build using either steel, or carbon fiber. The learning processes for each material is probably more different than the respective construction processes. Some of my builds are for commission, some are for experience. I donít market (unless you count a primative website), focusing my efforts within my local community. My shop isnít weatherized, limiting me to about six months of building a year; itís a small shop, about 9 x 11. To get work done, I move my wifeís car out of the garage, and spread things out until itís time to shut down for the night.

Iíve focused on road bikes, ranging from rando to racing. This summer calls for building a couple of cross bikes Ė and weíll see how that goes. My first love is the steel frame Ė and where I started my building odyssey. But, carbon fiber is very popular. People came to me asking me to build with it Ė so that has been a medium into which I naturally expanded.

The aesthetics of steel and carbon fiber are obviously different. Apart from some logos, and my ideas of frame design, there isnít much that ties my steel and carbon frames together. On the other hand, Iím still trying to figure out what are/will be my signature licks on a frame. So maybe Iíll find something to unify the two materials yet.

For steel, there have been many sources within the community to guide my methods and materials, which has been great! We stand on the shoulders of giants. Carbon fiber, however, has been a bit different. I havenít room (nor electrical circuits) for an oven to cure pre-preg materials. Thatís a shame because I think they are easier to handle than wet layups, and this has put me outside the mainstream of carbon-fiber frame building. Consequently, Iíve relied on sources outside of frame-building.

Most dry uni-direction fabrics arenít suitable for the complex shapes of a bicycle frame. They donít happily drape or conform to the required shapes. On the other hand, woven fabrics lose some of their strength because the threads bend as they cross each other. Through luck, I have found sources for rare fabrics that address these issues. These fabrics are made of layers (from 2 to 9) of uni-directional fibers, woven together loosely with stretchy threads, so that the fabric drapes easily and keeps the layers properly oriented to each other, while building up the joint. Cool stuff, and I hope I can continue to source these materials until such time as I move to pre-preg.

For all that has been cool about working with carbon fiber, the process leaves doesnít give me the tactile impressions of working a tool against steel.

Note: I have a drill press, but no other machine tools. This isnít a metaphysically defined setup Ė I just donít have the space or money to play with machine tools. So I push a file, saw, or sandpaper against steel tube and fittings by hand. And I find that this gives a greater feeling of creating something (at least for me), than does working with carbon fiber.

Donít get me wrong, both methods build a great bicycle. And either bike can be beautiful. But there is something more intimate for me about building with steel than with carbon fiber.

Where am I now? Well Iíve built around 30 bikes. Iíve been insured since the beginning. Iíve cut up lots of bikes, and thrown out my share of partially completed frames and/or forks. But my finished bikes seem to work well for their riders. My build times are improving and the mechanical processes are becoming more rote. More importantly, I enjoy what Iím doing. So Iíll keep at it, and one of these days show up at NAHBS.

Before ending, a few props are necessary:

1 Painting is hard, but done well it can make almost anything look good. Thank you to all the painters out there.

2 Thanks to the community of builders and their willingness to share.

3 A big shout out to e-Ritchie, who has done so much to keep this community thriving over the years.

4 Thank you Too Tall and the V-Salon for the opportunity to share my story.

Likes:

Likes:

Reply With Quote

Reply With Quote

Bookmarks