Dear Guest,

Please register or login. Content don't create itself!

Thank you

-

Re: Llewellyn Bikes

Re: Llewellyn Bikes

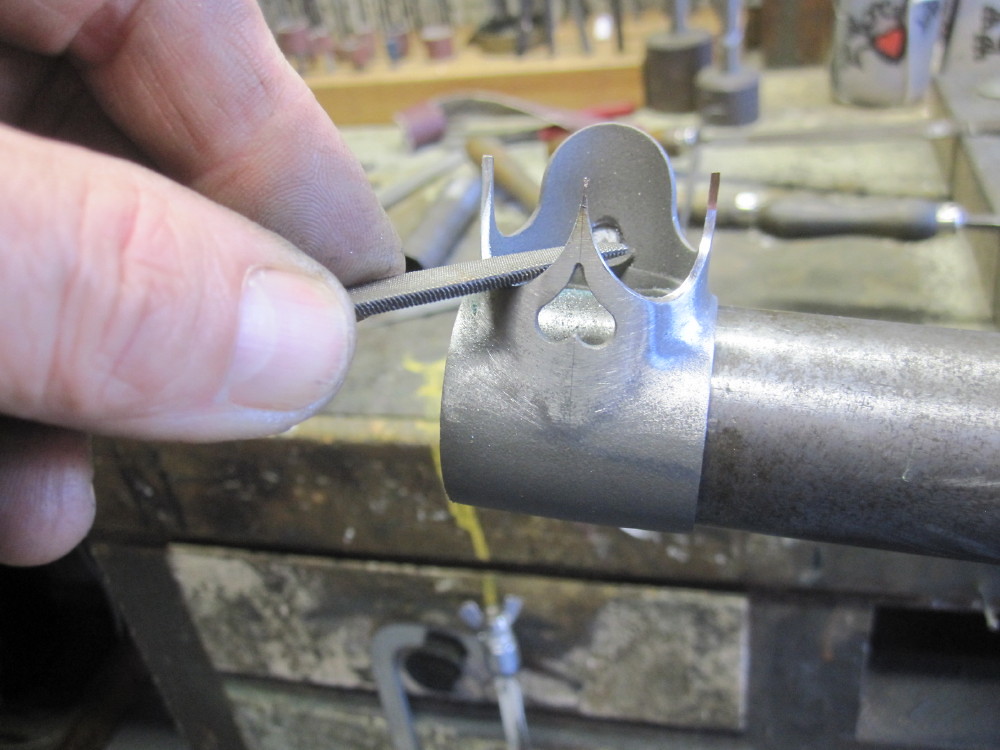

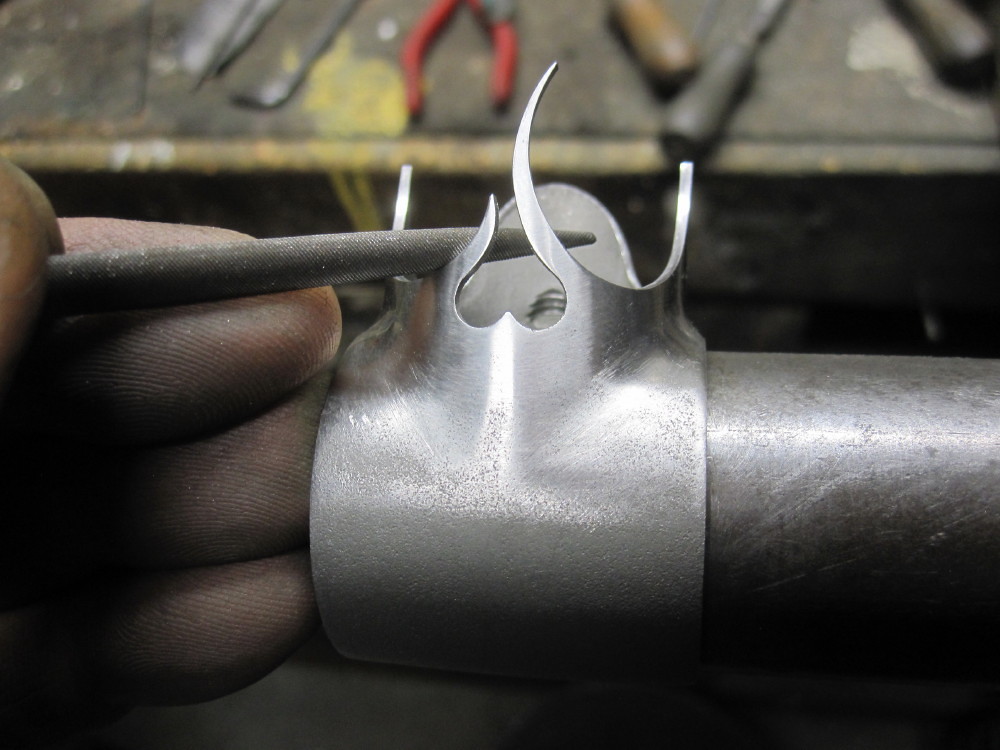

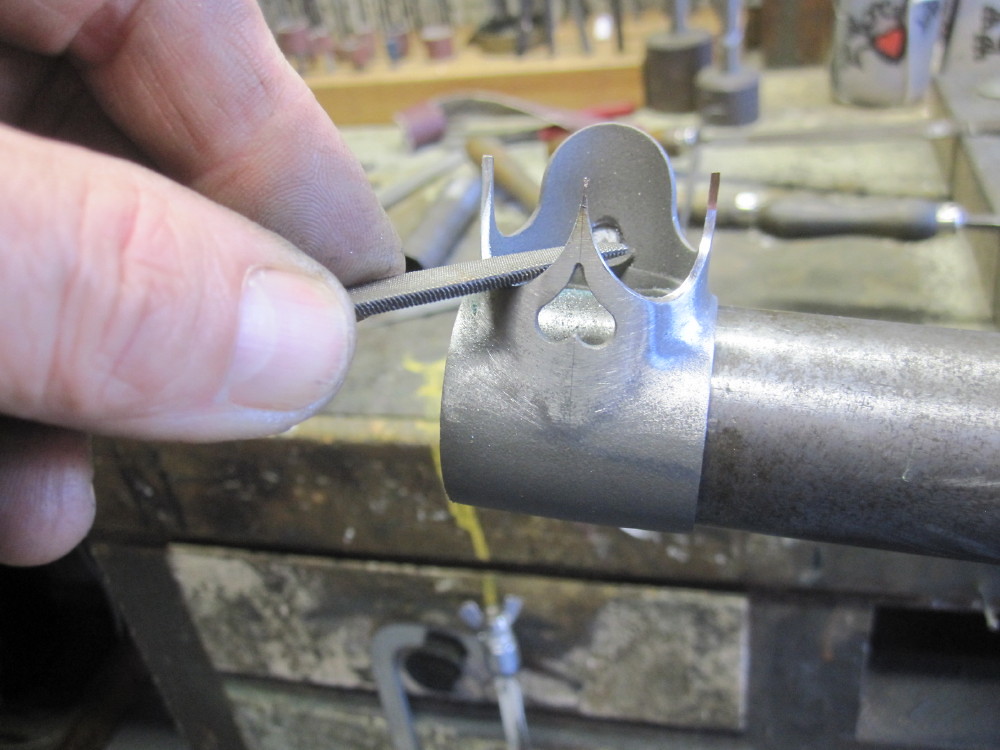

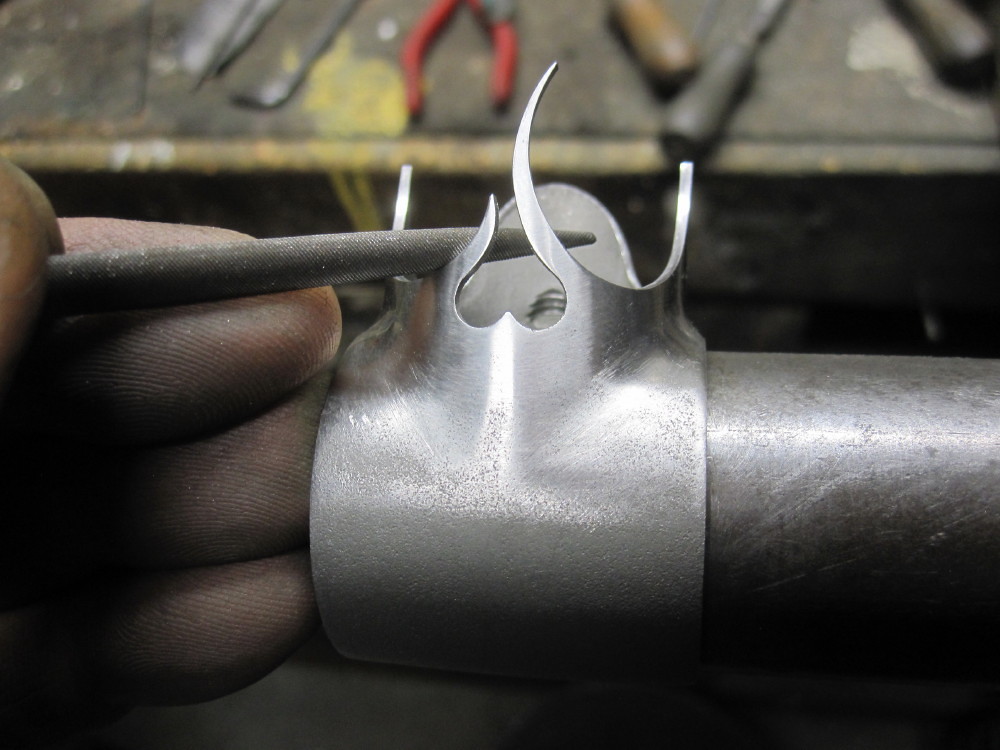

This crown has been Dazza'ed

I am pleased with the out come of the curves

It is not about me, it is about the bikes I can make for ya

"Most people wait for the muse to turn up. That’s terribly unreliable. I have to sit down and pursue the muse by attempting to work."

Nick Cave

-

Re: Llewellyn Bikes

Re: Llewellyn Bikes

Originally Posted by

Dazza

This crown has been Dazza'ed

Isn't that what Jennifer Love Hewitt did to her vajayjay?

-

Intro Why do I design and produce my frame castings and parts

Intro Why do I design and produce my frame castings and parts

Why do I design and produce frame castings and parts for steel frame construction?

There is a fair quantity of frame fittings and lugs on the market for a frame builder to choose from, much of it is from the 80’s and early 90’s era when steel frame production was ubiquitous. It is a pile of toil and expense to design and produce new casting designs, so why do it?

During my normal daily work at the bench making frames I found those 80’s and 90’s frame parts and some more recent designs lacking in many ways, they:

• do not exist for particular frame geometry, thus restricting design considerations.

• do not allow the builder to modify them for aesthetic or design considerations.

• didn’t exist for larger tube sizes which are better suited for use in frames for the larger and or heavier rider.

• are missing important design features that belong in 21 st Century lugged steel frame construction.

• are time costly and difficult to use correctly or to modify for design considerations.

Right from the start and to this day I do not design and produce new parts to exploit a perceived demand in the frame builder’s market, but firstly only to fill a need I have in the Llewellyn workshop production. However the initial design, tooling and production costs for new frame fittings are considerable and my own in-house production volume would never recoup these costs. To recoup the considerable expenditure I sell these Llewellyn parts directly to other builders or via my agents in the USA and Europe.

I will start with an out-line of the investment casting process and then follow a chronological order discussion of the Llewellyn parts I have created and give a short rational of the “whys” of their creation and some of their features:

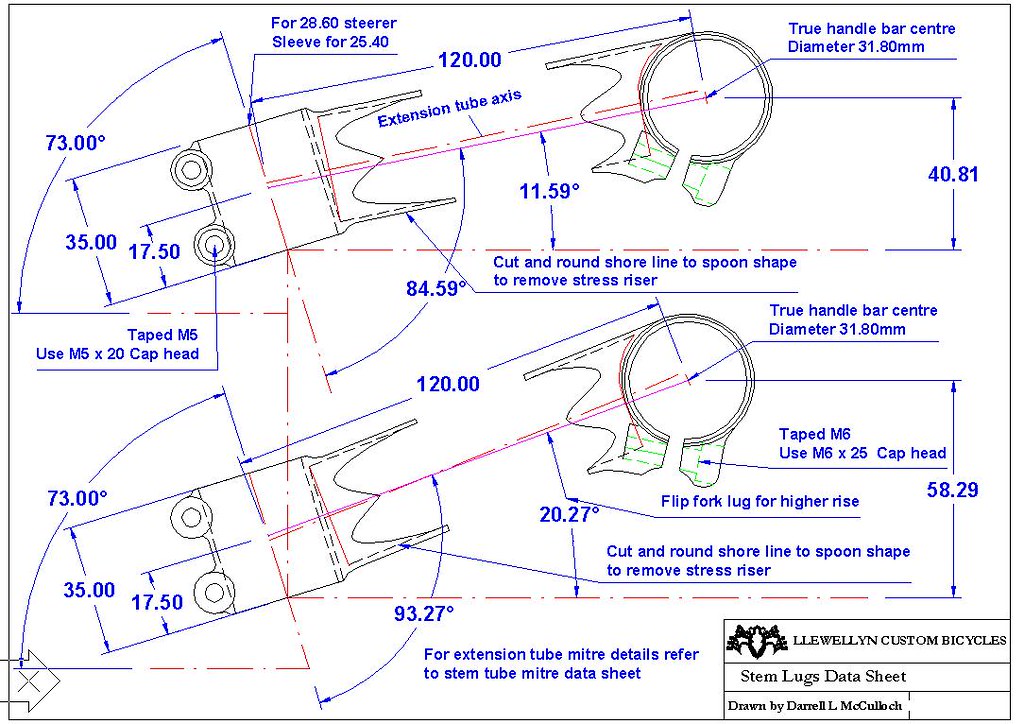

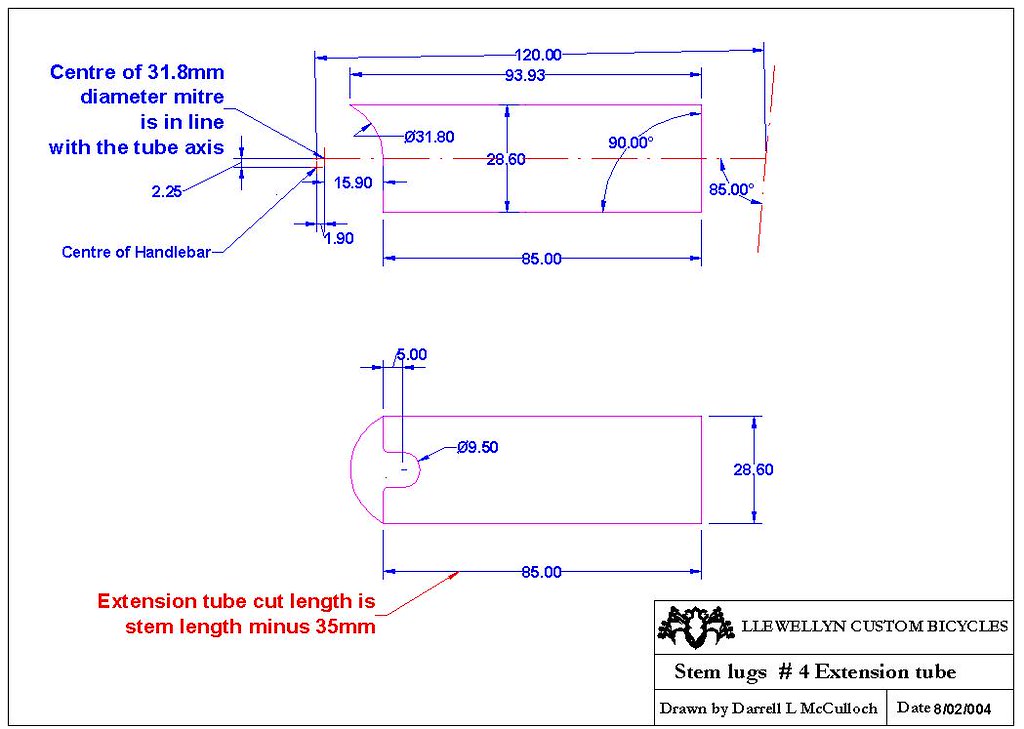

• “Llewellyn Stem lug set” – First stem lug set for 1” and 1 1/8” forks and 31.8 handlebars.

• “Crescendo” lug set – World’s first road frame specific sloping top tube lug set for XL (DOS) tubes.

• 30.60mm seat posts that fit directly into 0.50mm wall 31.7 seat tubes

• “Little fella” Gear boss – Stainless Steel investment cast threaded M5 DT gear cable boss, for 31.7 and 35mm down tubes.

• Manorina –A road frame specific sloping top tube lug set for OS tubes

• Track Dropouts – Track dropouts with enough material for placing on larger stays

• Dropouts – Investment cast dropouts with and without twin M5 threaded eyelets

• Limpets – Stainless gear and brake cable bosses

• Custodian – Level top tube lugset for OS tubes

• Cadenzia – Level top tube lugset for XL tubes in partnership with Dario Pegoretti.

• Rack bosses

• Nipper M5 seat tube binder boss. For lugless frame construction.

• XLH-4 Socket stay seat lug Cadenzia – Level top tube lugset for XL (DOS) size tubes.

• XLS-04 “Crescendo” Socket stay seat lug – sloping top tube lugset for XL (DOS) size tubes.

• Project underway, new process for casting, custom designs and a new frame set with lugs and fittings for mega tube size. Why, because I get asked for this.

• Projects in the wind, decent fork crowns that ease the builders toil and work well and look sweet

• Project in the wind, decent BB shell that ease the builders toil and work well and look sweet with correct angles.

• Socket seat lug for Custodian and Manorina lugs sets (OS tube size)

•

Please feel free to ask if you have any questions. If you want some of these goodies, you know where to find me 😉

-

Part One. The Llewellyn Casting design story.

Part One. The Llewellyn Casting design story.

Part One.

The Llewellyn Casting design story.

I stated working at age 16 Hoffy Cycles October 1979 for the owner Eric Hendren, I went there because I wanted to be a frame builder of custom bicycles. (the “why” is another story) At that age my 16 yo rose tinted glasses were very bright. Eric was using mostly pressed lugs and BB shells from his stock of Tange parts he had stashed in large tins in any corner that was convenient on the floor. This stash was a result of a trip to Japan he won via the bicycle trade. Around this time investment cast BB shells and lugs were starting to make their presence, mostly Cinelli if I recall. I was infatuated with all things concerning frame building and hand-made steel frames was ubiquitous in the quality cycle world. It was long before the corporations would arrive, we had no idea of what was to come, we lived for the time, rode bikes, trained and went racing and spent our scarce wages on bikes, travel, hotels and racing.

The picture is of me holding a Tange BB shell, that if you look closely you can see it is Blued for marking out and I had cut a playing card in the DT socket and most likely it had a H on the bottom of the shell. I would take the lugs home in my back pockets and would drill and file in a corner of bedroom. Why in my bedroom, because mother was very ill and it was the only safe space to do this and I was not allowed to set up a table with my little vice in the garage. I would get $15.00 for a set (enough to buy a training tyre) and Eric would use them on the Hoffy frames when the customer requested this detail. In the pic below Eric is actually repairing a striped thread in the BB shell of a 3 speed roadster. We fixed normal stuff and got it out the door and back on the road. Can you imagine shops doing that now? Unless they can throw it away and order the new part on line and then bolt it on with a “torque wrench” and so claim they are clever bicycle technicians while you wave your CC card over their machine, they are effing stumped ! You can also see some Reynolds tubing boxes on the shelf. On the other side of corridor beside the shop was the hairdressers and a couple of very nice young lasses worked there. It was absolute torture/frustration for me as they walked past the big sliding doors next the work benches to the lunch bar.

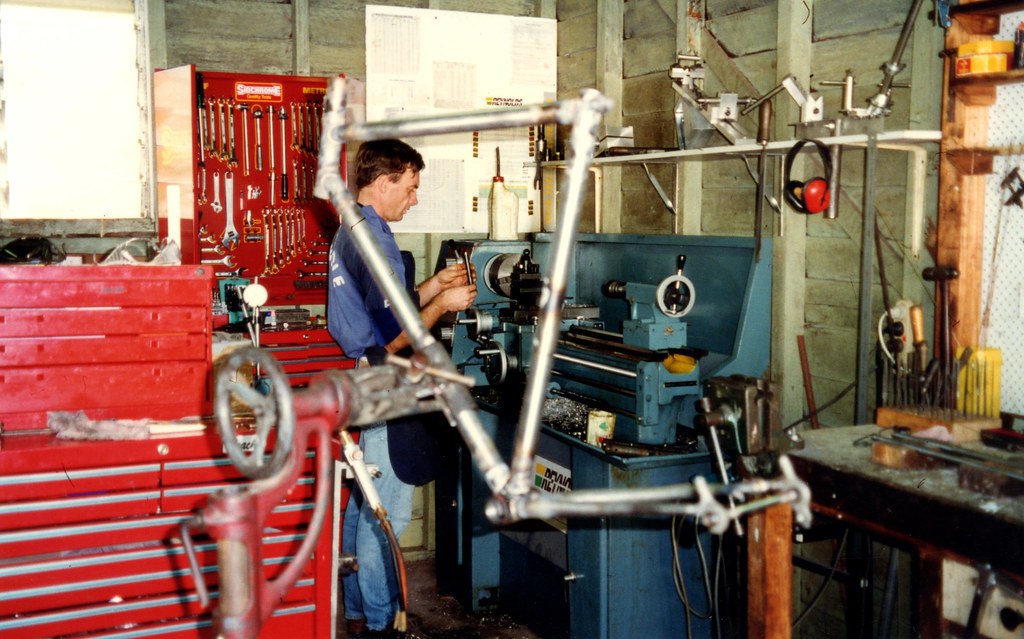

Workshop Hoffy Cycles Sandgate Brisbane circa 1984. Darrell McCulloch and owner Eric Hendren.

-

Part Two The Llewellyn Casting design story.

Part Two The Llewellyn Casting design story.

Part Two The Llewellyn Casting design story.

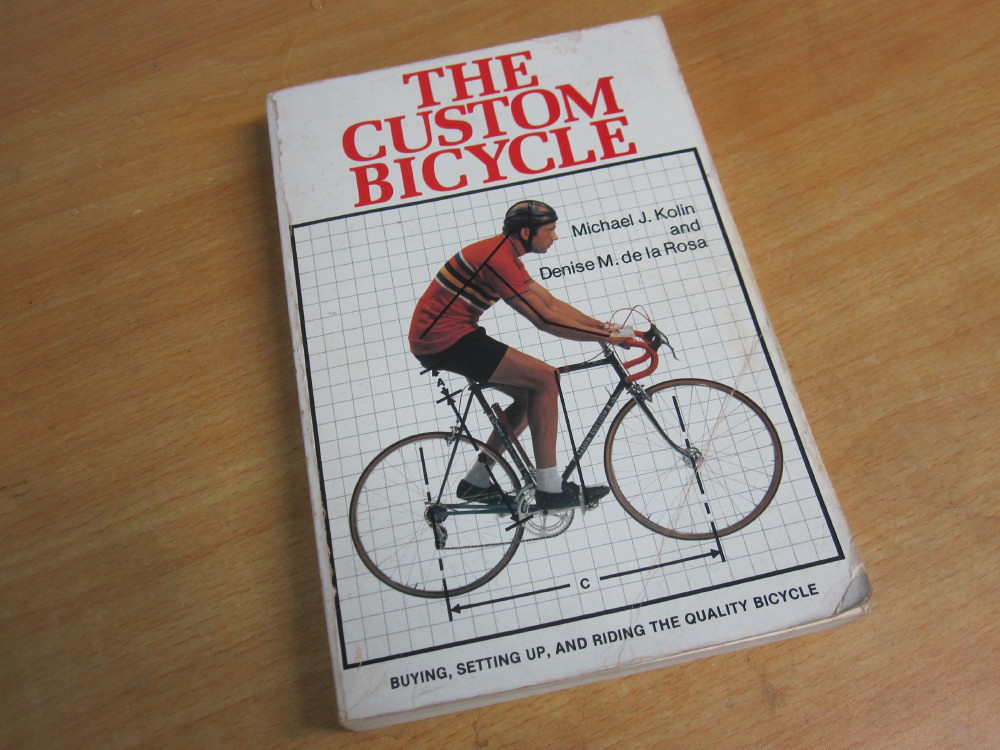

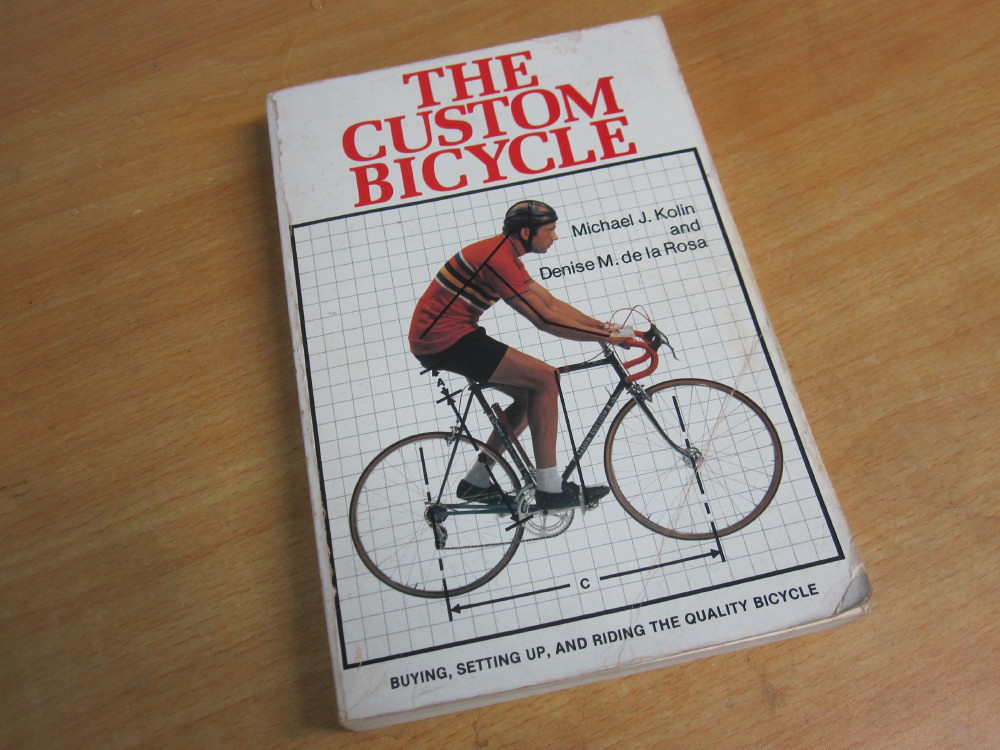

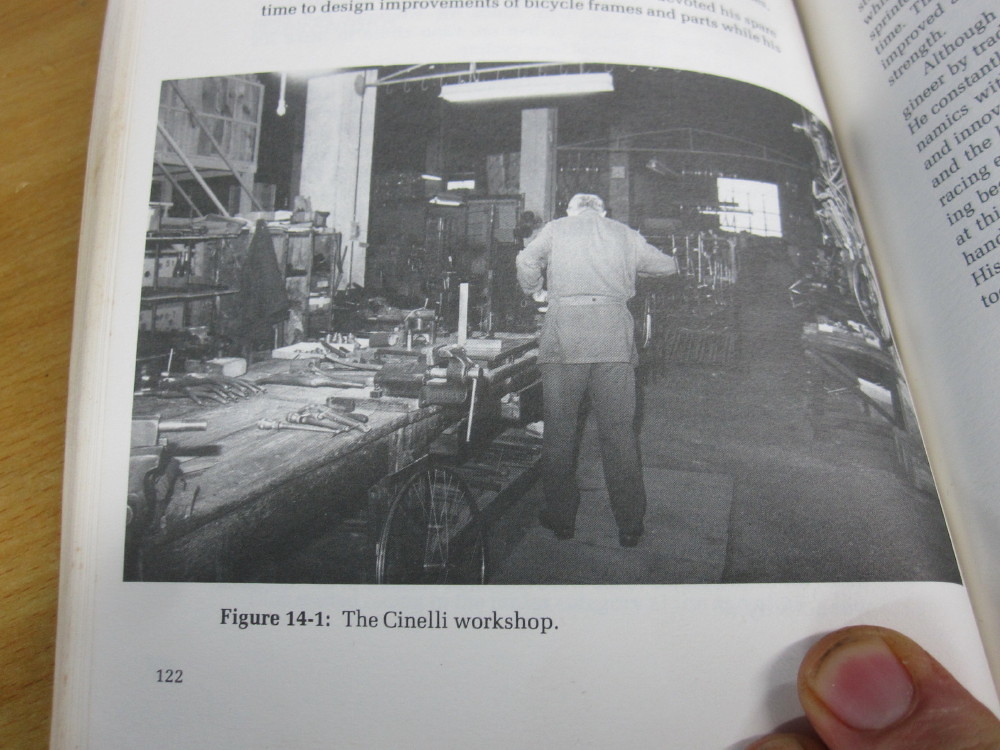

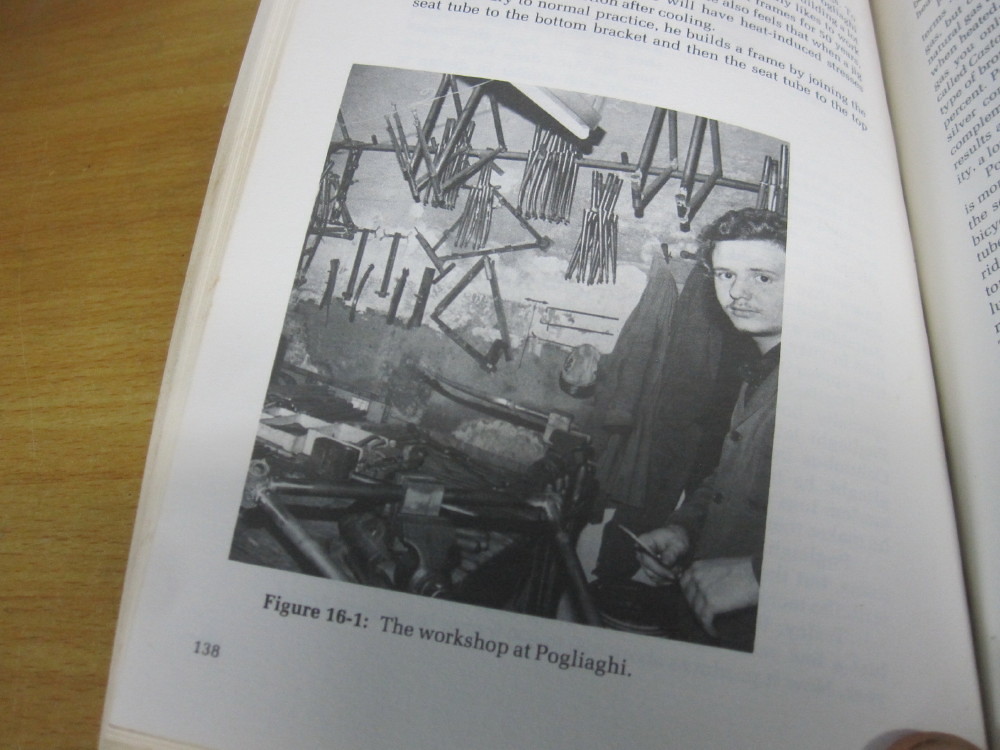

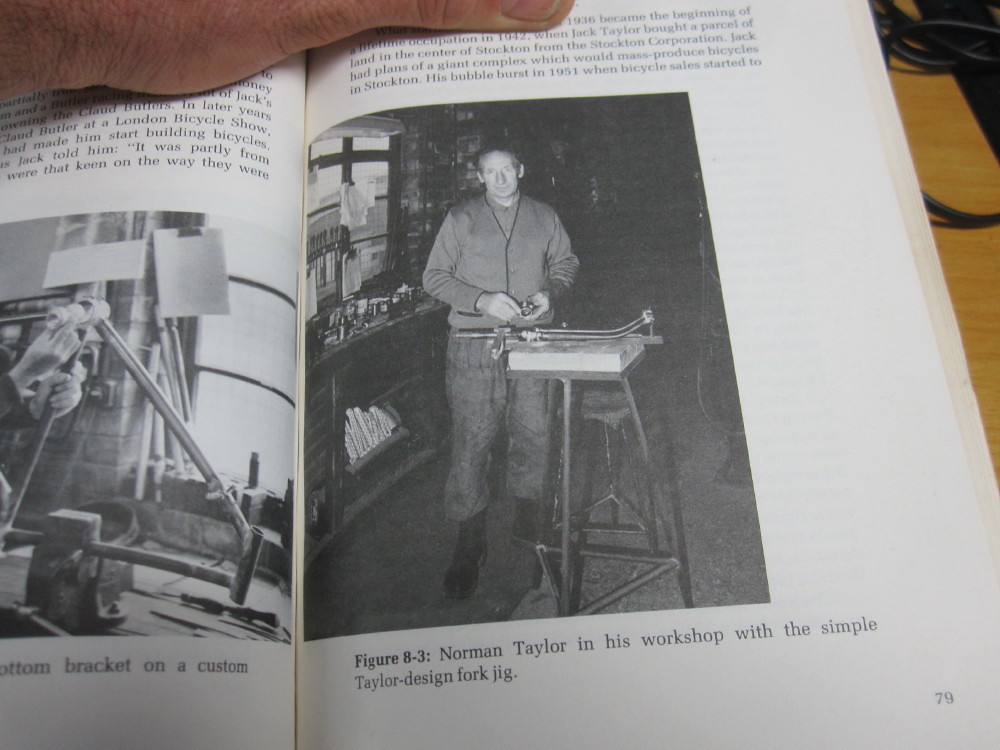

In Queensland it seemed we lived in isolation from the world of frame building. It was out there somewhere but what was out there seemed bigger, brighter and more glamorous than Brisbane according to the bike magazines. If you went to the summer track carnivals you would see 75% of the bikes being ridden were from Hoffy, if you went to the winter road races you would see 50% of the riders astride a Hoffy, all made by Eric in Sandgate. We saw some frames from interstate and the occasional imported Italian frame set but it was Hoffy frames everywhere. Keep in mind the race scene was all there was, very little cycling was done as a recreational past time back then. The adverts for investment cast frame lugs and parts were appearing in the pages of cycling magazines and I would over scrutinise any picture of frame making or a workshop that appeared on the pages. One particular book that I absorbed at the time and was a huge motivation was “The Custom Bicycle”. Wow, I thought. ......... Meanwhile Eric kept whistling to the tunes on 4BH radio and I longed to listen to the test cricket on the radio while Suzy and Tania kept walking past on the corridor beside the bike shop to the sandwich bar. Sigh!

-

Part Three The Llewellyn Casting design story.

Part Three The Llewellyn Casting design story.

Part Three

I lived with an urge, perhaps an unstable lust for frame making. It was only the magazines and a book or two I honestly recall where I was standing when I thought “one day I want to design and make frame casting and have own bike shop with the frame building out the back.” I really did have that thought go through my head. I was standing at the work bench with aching legs from the 2 hours of training before work commenced at 8.00am, doing some mundane task such as rebuilding a Shimano B type coaster hub in some kid’s bike for the 4,000 th time, pondering, day dreaming and needing to sate my desire to do more frame work. My enthusiasm for the frame building, to take it further was far greater than the situation would or could allow. Eric has to make the shop pay it’s way and it was toil, toil and persevere at the toil and I was there to do the tasks, chores and earn my wages. Meanwhile I was trying to stay sane with the family home situation by shutting out everything but for training, racing, work, reading and anything frame making related. It was around this time I bought my first lathe, a little Emco Unimat that I kept on a table in my bedroom. I was starting to realise “a lathe is a beautiful thing” .

The day did come , 20 years after the thought went through my cranium but there was a few more steps to take on my time line.

-

Part Four The Llewellyn Casting design story.

Part Four The Llewellyn Casting design story.

Part Four

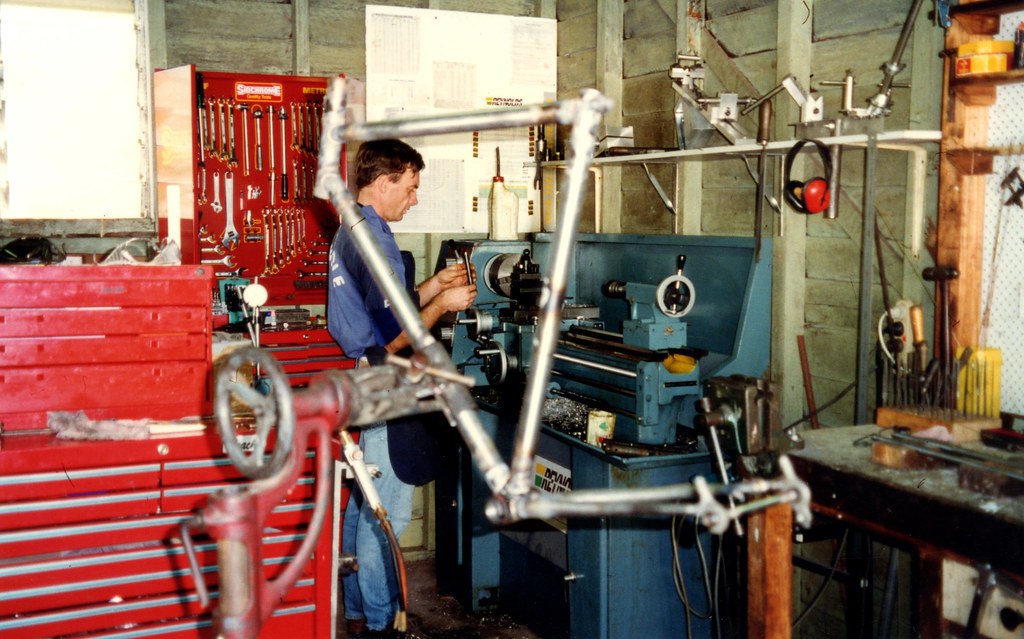

Six years at Hoffy Cycles and I had become severely bored. There was a limit to how many coaster hub rebuilds I could suffer. I made my first two complete frames the year before and now I was restless. I chatted to Eric, I asked if I could do more frame building work, I wanted to do more and develop the frame building side, to make it brighter, newer, promote it, inspired by the Italians and I had that youthful enthusiasm that is yet to be dulled by the passing of many laps around the sun. Eric said , “yes, we will have to something……………..” Six months later no movement, then I jumped at the opportunity to work for another chap who built frames in Brisbane. I was 23 and I had to make the change. Any change would be good, but most importantly I was now making frames all day, which then allowed me to start progressing, on someone else’s time. Even my racing improved. I got my 6” lathe and a mill/drill, both of which I still use today. However a year later that frame making gig went bad, the owner and his partner had issues. Left me in the lurch, but two weeks later I got a job at the “Lifecycle” bike shop on the Normanby five ways. Working there was like working in the middle of a traffic island, no frame making but it was a good job and I had few good mates working there, so it was fun and got me involved with retail. It was some time in 1987 that the thought went into my cranium that it was time. Time to start making some frames under my own steam if I am ever going to make frames again. The first thing I bought in 1988 was my 200kg surface/inspection table. $2,000 was a lot gold coin for me back then. It left me broke and totally impossible to have a social life. But for me I wanted to have precision in the build process, so the most important thing is a good alignment inspection table. It should be the #1 tool in a frame maker’s workshop! I still had to wait till I could start making frames, so it was work full time, work in the evenings making jigs, learning the basics of lathe work (only ran the tool into the chuck once) spend every dollar on more tools and still no real social life. Early 1989 I was close to making my first frame as a registered business. No idea what to call the frames. I wanted something related to me, but not “McCulloch”or “Darrello” or one of the numerous other stupid suggestions put to me. “Llewellyn” my middle name, there that will do and I struggled to remember how to spell it. I liked having something that was not main stream but connected to me. So “Llewellyn Custom Bicycles” was registered as a sole proprietor and frame number 001 was made.

I made frames at night when not training or racing, worked on frames on weekends and worked full time during the week at the bike shop. I did start to have a social life, but a few wrong turns along the way, crash and burn etc. A few crash and burns is good for you eh!

I raced, got married. Stopped racing, worked part time in the shop and the other 3-4 days made frames. I had orders flowing. Made a lot of track frames, and 99% were racing bikes. Then I was a bachelor again, so I went to France with some mates and started racing before I was too old and to completely get it out of my system. Age 29-30. That was a great experience, I am very grateful I got to do a couple of seasons racing village races in France. Back to making frames in the summer and working at the bike shop. Came home from France after the 1994 season broke, with glandular fever but did I not know I had it then, got a fulltime job as the road cycling mechanic at the Australian Institute of Sport and with the national team. Lived in Canberra and in Europe. Worked the Worlds and the Atlanta Olympics. Washed Aussie team bikes in 23 countries. Came home, worked in bike shops and made frames and did 6-8 months stints till the Sydney Olympics and the worlds in 2000, now that was a big year. After the big year of 2000 it was time to stay home and ponder what is next.

-

Parts to come The Llewellyn Casting design story.

Parts to come The Llewellyn Casting design story.

More next week, got to go and listen to the Ashes contest on the radio.

-

Part 5 The Llewellyn Casting design story.

Part 5 The Llewellyn Casting design story.

Part 5 The Llewellyn frame casting story

While I was galloping about Europe, washing bikes in a different country every week (23 in total) the world of the independent bicycle frame maker was changing and it was never going to be the same. From about 1995 we could say that the Corporations were arriving, Giant, Cannondale etc. The bike industry was becoming commoditised like it had never seen or experienced before. The Corporation’s product was being mass produced in places where labour was cheap. The executives were realising their asperations through the efforts of others. At the Australian Institute of Sport the road team had Giant as a sponsor. Back then these bikes worked well in the harsh environment of a national cycling team. In early 1996 we had the team pictures being taken and the Giant representatives were there, explaining to me and others with extreme enthusiasm and gusto about the new frame size system they were introducing soon. Three frame sizes and with various seat posts and stems so we can fit a bike to anybody. GOOD GRIEF went through my mind! “What could possibly be wrong with that ? ” They thought it was the answer that had never been discovered……………… Any how the steady arriving stream of containers loaded with high end bikes to down under had begun. The bike shop retailers loved it, a phone call, a box arrives, give the tyres some wind, “CA CHING” went the cash register and even that sound was soon to be gone as the consumer racked up their debt on the “fantastic plastic”. The banks are also happy, but they would never admit it, they had their catheters in the punters wallet for a steady income stream of their interest-blood $.

The $ flowed, cycling as we knew it was changing and it was no longer the underground sport that we “Special dedicated cyclists” understood. It was now for the masses and that is good but also a bit sad as something was lost and gone forever. The masses are riding expensive and inexpensive bikes on laps around the river and getting some knick time at the coffee shop after watching the TDF on SBS the evening before. New brands that were popping up when numerous entrepreneurs went to the Taipa show with cash to make the orders and have the containers shipped with their decals. It was feeding the bike industry like never before.

At first it seemed good to me, then to me it seemed shallow and it was about selling an image, it all became a bit kitsch to my mind. People actually thought you need to buy a set of Red coloured special climbing wheels to be able do a lap over Mt Mee on a Sunday with three types of special scientific formulated packaged food bar in your back pockets along with the C02 inflators. Something we did in the early morning before work on our training hack bikes with a banana or a piece of fruit cake in the back pocket with the Zefel pump strapped under the top tube and we rode hard with grace on the pedals. The bike magazines and the internet are telling them this is how you must ride or your health and your cycling enjoyment will be compromised. SIGH!” How to be a better climber in five lessons and …………………” Sigh!

Anyhow, I wanted to stay home in 2001, I had some weeks off over the summer, went back to the bike shop to earn a $. I lasted till lunch time on the third day, my brain evaporated. I could not do it, nothing wrong with the good people there at the shop, they were terrific, it was just that my time in the bike shops was over. It was time to go home and ponder about working for the first time in my life as a full time independent frame maker.

But things had changed, very big and different changes.

The pic is of me working on Deane Rogers bike under the feeble light of a sky light in what looks like a bomb site at the back of the Hotel in Columbia before the 1995 World Championship time trial. Big Mig won. The other pic is walking out into the stadium with the Aussie team at the Sydney 5 ring gig 2000, what a buzz that was.

-

Part 6 The Llewellyn Casting design story.

Part 6 The Llewellyn Casting design story.

Part 6 The Llewellyn frame casting story.

2001, I want to make steel frames. Every one tells me I am mad, steel is over. It is aluminium now. Aluminium is a terrible material for a bike frame for many reasons but…………………… I start the process, TIG welding courses and pondering the tool up process. I look at a PC for the first time. How does one work this thing ?

But I like steel, it is strong, beautiful and a wonderful material to work with. It can be used delicately, you can do so much with it and still have a very reliable structure, with brazing via brass or silver and even TIG is one is so inclined. (I am not so inclined) Still every one said I was nuts and I got many condescending remarks out there in the land of bicycles. The irony is that some of them now covet and even own some of my work. I made a vow to myself, ok, if it does not work out for Llewellyn Custom Bicycles within two years I will stage exit right and go off and be a farm labourer or drive a fork lift or drive suburban tin sets or whatever…………………...

Internet, digital cameras, typing, websites, forums , marketing, CAD programs, that was the evening hours after 10-12 hours standing at the bench, while the Australian Broad Casting gave me Radio National or the test cricket. There is a lot more to deal with in the frame making caper compared to the 1980’s and this means a lot more time is consumed that is not bench time making stuff that results in writting the invoice. It was then that my neck discs started to make themselves felt and my arches in my feet started that slide to errrr yukkkk. My grand-father said it was better to wear out rather than rust out but I did not expect to wear out so early. He lived to age 95.

There was no choice but to go down the path of fillet brazing funky shaped tubes from Dedacciai and Columbus. I had done a bit of fillet brazing in the 90s but it was 95% lugged frames back then. Sloping top tubes was the norm now and I did the occasional lugged frame. I got a fair bit of inspiration from Casarti frames in Italy for my lugless work. A couple of times I cast my eyes over their products during visits to the Milan Bike show. I was driven to persevere at the long hours of toil, mostly 7 days a week by the fear of failure. Every dollar was precious (that has not changed) If I failed it was because there was no more I could give. Most important that all of this was possible because I do not have any children. As long as I could eat and pay the mortgage I was OK. I tell this to many budding newbies. Then I had a bike test published in Ride Magazine in 2001 and that caused the phone to not stop ringing. YAY! Phew! By early 2002 I was confident I was still staying on the frame making stage and I could pay the mortgage if I lived cheap. I still did some moonlighting trips with the cycling teams here and there, a couple of Commonwealth Games and trips to New Zealand, France, Italy. That all helped the income stream and was an interesting break from the work bench toil.

The era of the Carbon infestation is getting closer. Tick tick tick tick…………………..

It is 2003, 20 years after that “moment that I can actually recall where I was standing when I thought “one day I want to design and make frame castings and have my own bike shop with the frame building out the back”

It was time to have a go at designing and producing my own invest cast frame parts, but how do I do this ?

-

Re: Part 6 The Llewellyn Casting design story.

Re: Part 6 The Llewellyn Casting design story.

This is really cool stuff, Dazza. Love the accompanying pix. That pic of you at Hoffy :) Look at that face. And that fillet bike looks might nice to me. Perhaps that part of the story is coming but did the little frog/toad join the Llewellyn team?

-

Re: Part 6 The Llewellyn Casting design story.

Re: Part 6 The Llewellyn Casting design story.

-

Whoops part 3B The Llewellyn Casting design story.

Whoops part 3B The Llewellyn Casting design story.

WHOOPS. missed a part, I do all this was while doing phone calls, deliveries and neighbours with Cancer.

Part 3 B

Even though I could not ride out of sight on a dark foggy night and my sprint finish was barely detectable with modern scientific instruments, I lived with an urge, perhaps an unstable lust for frame making and racing, I kept finishing second or third until I began to wonder if I was nuts? I trained in all weather, because Sean Kelly would not hesitate to be out training in the Belgium sleet and if the others are at home warm and dry and perhaps cuddled up, I was keeping fit, getting tougher and their form would be slipping……. I did a lot of thinking when training, I think long solo rides are good for your mind, well I convinced myself that it is good thing. No strings in your ears back then, just the sound of the Sanyo Dyno Power rattling on the tyre tread while you squinted to see the pot hole with its feeble 3 watts and that is only when you were going at a decent clip downhill, while the drizzle soaked through your woollen under shirt and your feet turned to prunes, pondering the meaning of life and wondering where and what my school crush, Sonya Housman is……………………………… agh sh-t the Dyno Power is slipping on the wet tyre tread………………… (Some will know what I speak of 😊)

A period of time did come when I had my doubts. Is this frame making caper a wise career choice? All my mates were earning 3-5 times what I was earning or they were finishing Uni degrees. I pondered for some months while riding or standing at bench rebuilding a rusty gummed up Sturmy Archer 3 Speed hub for the 1578 th time, I recalled what Susan Wright who sat next to me in year 7 at primary school said, (or was it that I sat next to her?), any how she had a brain the size of a planet. One day she pretended to read my palm and she said, “you will be a pauper” Such was my ignorance I had to ask her what a pauper is?

So the moment came, when all my momentous life choices are made, probably while riding home 20kms from the shop, usually in the winter dark, most likely raining or into the howling westerly, “Susan is right, stuff it, deal with the consequences of whatever happens, I might well be a pauper via the bicycle world and worse comes to worse I will be just a bike shop owner/worker scratching a dollar here and there, so be it”. This was in the time before cycling became heavily commoditised. The tragedy of this makes you weep eh? No? Oh well, I am not making any of this up. Race now while one’s physical powers are at their best, I never wanted to race as a vet (and I never did) This leads to the moment that I can actually recall where I was standing when I thought “one day I want to design and make frame castings and have my own bike shop with the frame building out the back.” I really did have that thought go through my head. I was standing at the left end of my work bench with aching legs from the 2 hours of training before work, doing some mundane task such as rebuilding a Shimano B type coaster hub in some kid’s bike for the 4,000 th time, pondering, day dreaming and needing to sate my desire to do more frame work. My enthusiasm for the frame building, to take it further was far greater than that current situation would or could ever allow. Eric has to make the shop pay it’s way and it was toil, toil and persevere at the toil and I was there to do the tasks, chores, a wee bit of frame work and earn my wages. Eric was a good boss, I was fond of my time at Hoffy Cycles. Meanwhile I was trying to stay sane with the family home situation by shutting out everything but for training, racing, work, reading and anything frame making related while I started to expand my metal working urges via the pages of “Model Engineer” magazine. It was around this time I bought my first lathe, a little Emco Unimat that I kept on a table in my bedroom. I was starting to realise that “a lathe is a beautiful thing”.

-

Re: Whoops part 3B The Llewellyn Casting design story.

Re: Whoops part 3B The Llewellyn Casting design story.

Originally Posted by

Dazza

reading and anything frame making related while I started to expand my metal working urges via the pages of “Model Engineer” magazine.

I have enjoyed this series of biographical posts Dazza. I am glad you mentioned "Model Engineer". I taught myself how to make musical woodwind instruments, or at least how to make the tools to make musical instruments, by reading "Model Engineer" in the 1970s, 80s and 90s. The articles were written by people who had possibly done apprenticeships in the 1930s, 40s and 50s and had a breadth and depth of knowledge of metal work that has largely disappeared and may never be repeated.

-

Re: Whoops part 3B The Llewellyn Casting design story.

Re: Whoops part 3B The Llewellyn Casting design story.

Originally Posted by

Paul Jacobs

I have enjoyed this series of biographical posts Dazza. I am glad you mentioned "Model Engineer". I taught myself how to make musical woodwind instruments, or at least how to make the tools to make musical instruments, by reading "Model Engineer" in the 1970s, 80s and 90s. The articles were written by people who had possibly done apprenticeships in the 1930s, 40s and 50s and had a breadth and depth of knowledge of metal work that has largely disappeared and may never be repeated.

Yes, I am in full agreement with you, the wealth of information from "Model Engineer" is endless. The Magazine is over 110 years old and I have subscribed since 1985 and enjoy receiving every fortnights edition my brain food.

-

Part 7 The Llewellyn Casting design story.

Part 7 The Llewellyn Casting design story.

Part 7 The Llewellyn frame casting story.

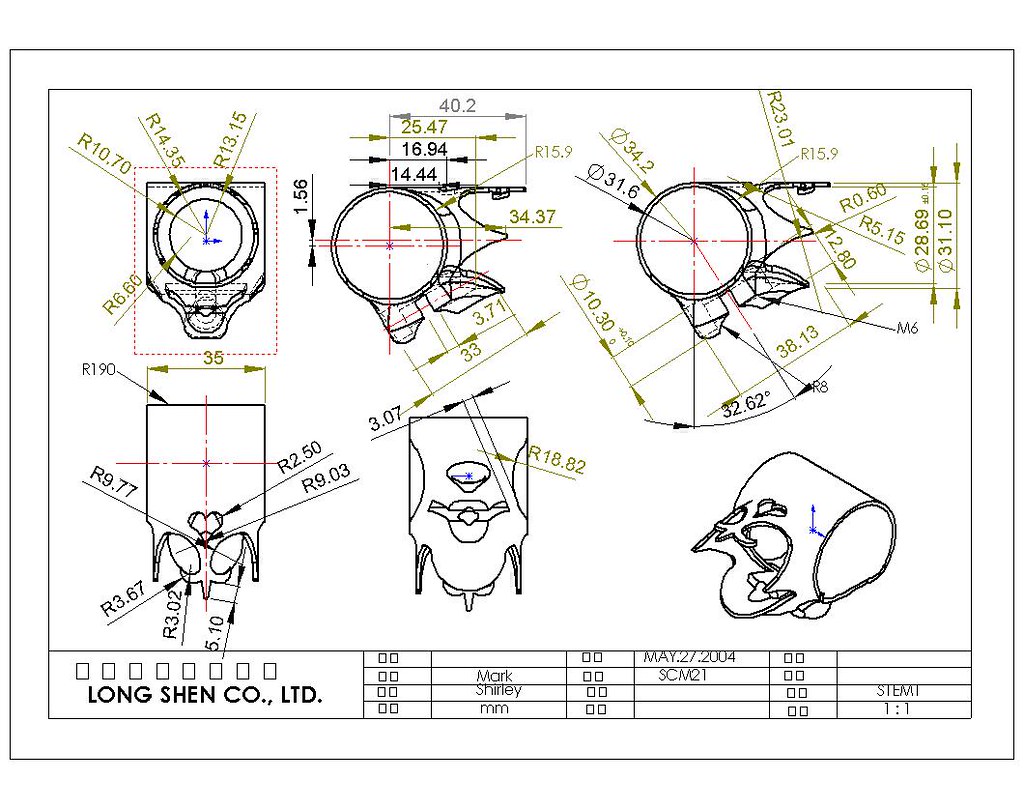

For many years I was making fillet brazed stems to compliment a client’s Llewellyn bike. This came about in the 90s when I was asked to make quill track stems for the trackies. We had a good and fun track racing scene in Queensland but I felt the introduction of summer crits started to demolish the track season which I was not all that pleased about. The growing MAMIL population found it easy to sit on a wheel going around some dull flat circuit that did not even have a corner in it that you had to lift a pedal for, pretending they are Robbie McEwen, compared to riding on the track which took considerable skill, fitness and race craft. (Robbie did ride track in his early days) It is hard to be just an equipment poser when racing track, you look like a real dork if you cannot ride/race the track with grace and technique. Any how I made the track stems from Chromoly tubing, machined the clamps and binders for the steel track bars on the most beautiful thing, a lathe. Chaps and lasses won many Aussie titles on Llewellyn frames and there was a couple of world junior champions as well, on their way to the Aussie national team. Then someone asked me to make a threadless stem for their new lugless Columbus Mega tubed Llewellyn road frame. Yeah, I can do that, so I then made a threadless fork stem for him and that resulted from then on in most Llewellyn frames having a matching stem perched on the fork. Then later I added a machined head spacer from aluminium to grace the set-up, rather than a stack of alloy or plastic spacers. It was a frame, fork, stem, spacer to complete the set, it all was becoming what I consider a “frame set”. It helps flesh out the order book and adds to the invoice which means you stay in business. After all, this is not my hobby, it is my chosen path of professional expression. As the first decade of 21st Century rolled on I was making an increasing number of lugged frames again. YAY! I was trying to stretch my skills with the stainless polished caper, but I began to be dissatisfied with matching up a lugged frame with a lugless stem. It did not seem right to my thinking and my aesthetic desire. I tried one of those lugged stem kits that LongShen produced, but the bar lug had issues, it was for a handle bar that needed to be 26.80 mm in diameter (which is nonsense), so I had to braze a sleeve in and then bore out to 26.00mm in the lathe to fix that. The fork clamp was only for 1” steerer tubes. The extension tube was drop shaped, which was a terrible thing to mitre and fit up for good brazing and it looked too deep for my aesthetic tastes. I made only one stem using that lugged kit. Move on said I.

Around 2003- 2004 the urge to create and produce a stem lug set that does not exist for my needs at the Llewellyn workshop bench was festering into a “need to make happen.” 20 years after that thought passed about inside my cranium “that one day I want to design and make frame castings” I started seriously going down the pathway to do this.

I will often be working away at the bench and a thought will come into the light, I have to stop and go to some scrap paper or my work diary and scribble down ideas and designs. I have done this since I was a budding artist at primary school. I was encouraged to always put it on paper before it is lost. This ingrained habit can cause the flow of some work and other tasks such as typing, posting on forums to be broken as one crams more into each working day, but it is important to me to not to lose the moment so I break the flow and sketch, scribble or make the phone call and so on. Some times I wish I kept all of these drawings and sketches, however I am not on a mission to make a legend of myself and thus keep every bit of paper of my life to regurgitate the banal details to others at a later date or for some museum. I am encouraged by others and with some hesitation on my part to tell the story of Llewellyn. Yeah, perhaps it is part of marketing as well, however I will only give a limited energy to it, because I have other metal working hobbies that scream at me to devote more and more time exploring. If I had the millions in the bank, I would stop making bike frames this afternoon as I can easily sate all my metal working desire via my model engineering projects. Anyone about who would like to Llewellyn outright ? 😊

-

Part 8 Casting # 1 The Llewellyn Stem lug set.

Part 8 Casting # 1 The Llewellyn Stem lug set.

Part 8 Casting # 1 The Llewellyn Stem lug set.

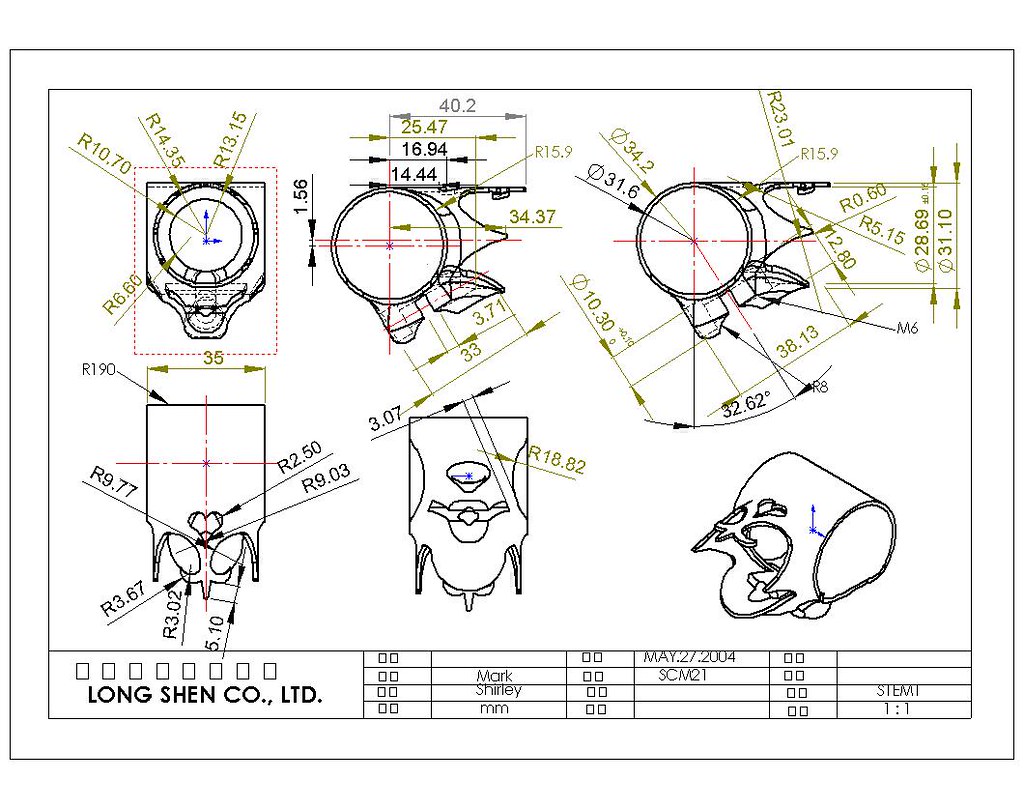

The sketches of my stem lug desires commenced, I had chats with Kirk Pacenti and a few others about how to go about this project and seeking a foundry to do the investment castings. I had started self-teaching myself via text books in the evenings the basics of 2D CAD drawing and I generated some 2D CAD drawings of the determining dimensions of the lugs. I also contacted investment casting foundries in Australia to consider casting the lugs however when I showed them the drawings they said it cannot be done with such thin walls at 1.20mm. I showed them bike frame lugs castings with 1.20mm walls from Taiwan. That had them standing on their batting crease as if Shane Wayne had bowled around their pads an unplayable delivery that spun and fizzed off the pitch to rattle their stumps. (think of the famous first Test delivery to Gatting) The huge amount of time this project sucked up is immense. It filled a significant part of many days and many evenings and I still had to make frames to fill the orders and earn a $ to live with and also to finance this casting folly so working weekends was required. I would have made more $ if I spent that time filling the supermarket shelves at night but of course, the motivation was to make the vision or dream folly a reality, even if it was just once in my life. It was all to be part of my journey and part of my time line. The drawings evolved and I made the decision to go off shore to Taiwan for the foundry. LongShen have been doing a large share of the steel frame building world’s casting for some time and a few of my colleagues had recently had them successfully involved with their projects. The internet made all these communications much easier than in the decades before and the sharing of info was much increased compared to the 1980’s. Crikey, the silicon chip has moved the world and bicycle frame building was a tiny part of it all.

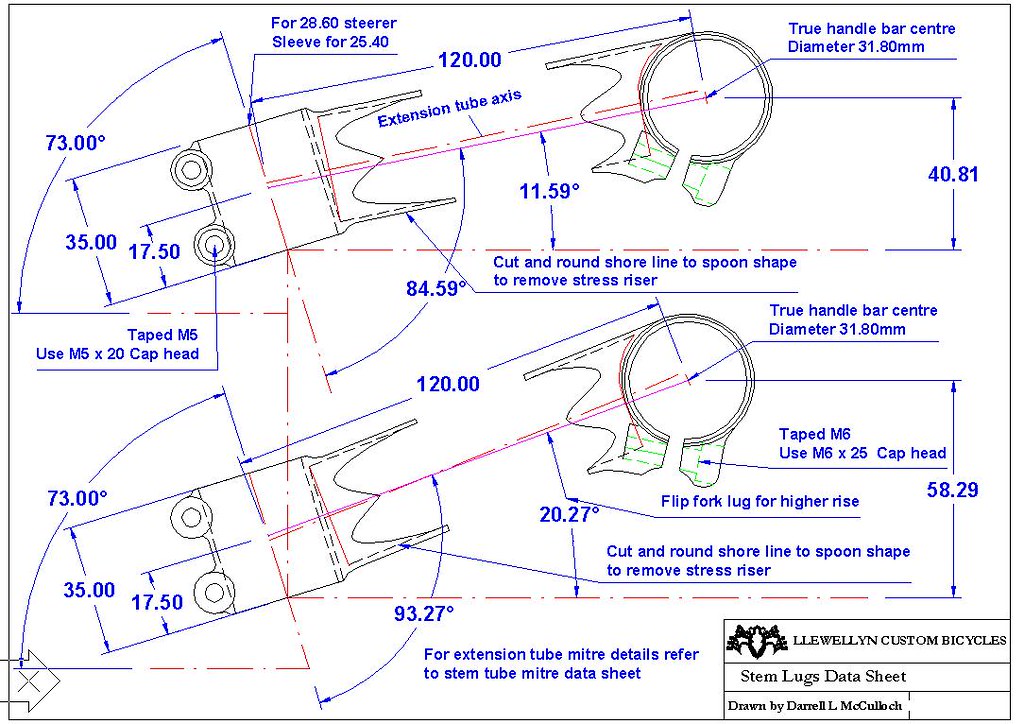

The most important desires and features were to be

• The fork lug to fit directly onto a 1 1/8” fork steerer tube (28.6mm)

• The fork lug to also fit 1” (25.4mm) with an alloy sleeve such as the one Deda Elementi make.

• To be able to flip the fork steerer lug to get different stem rise amounts

• The handle bar lug to fit 31.8mm handle bars.

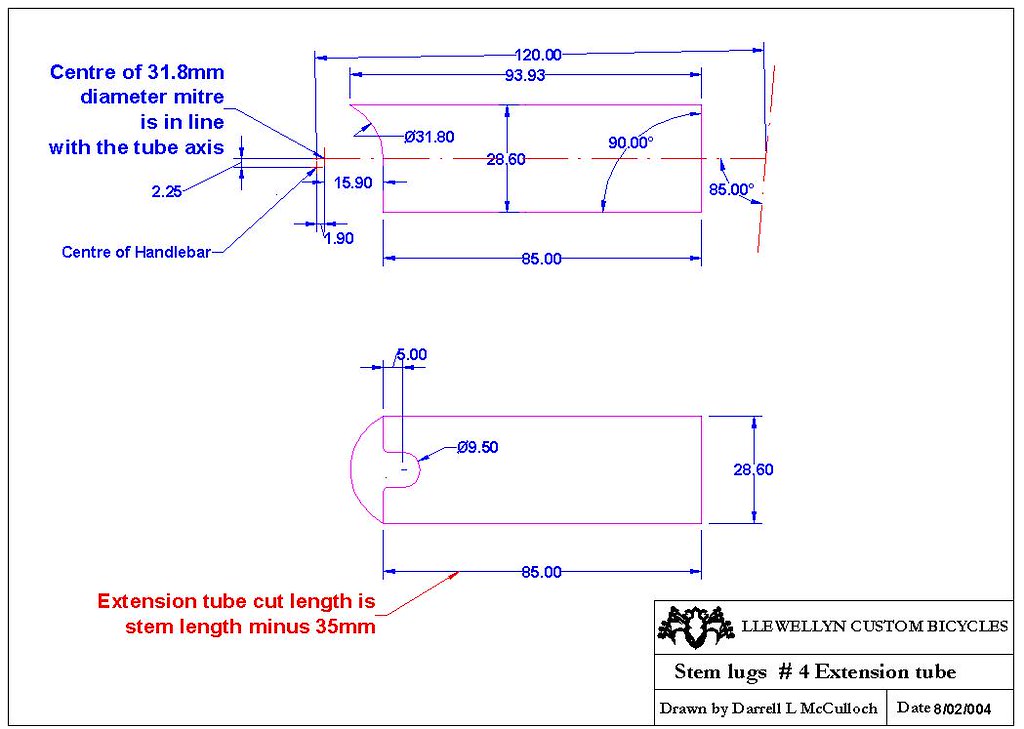

• To use a round 28.6mm extension tube for adequate strength and to match the top tube diameter.

• Easy mitring of the 28.6 diameter extension tube and easy perpendicular alignment of the handlebar axis to fork steerer axis.

• Single M6 bolt was chosen for the bar clamp, because the stem is made to length for the bespoke fitting bike and not about seeking a position off a bike shop floor size. Also the aesthetic was to be sweeter and less material required.

• Room on the lugs shore line for the builder to alter to compliment the frame’s lug shapes.

• The lugs would only be cast in stainless steel to avoid corrosion with interface of the handle bar and fork.

I fabricated a sample of the bar and fork lug from machined tube and stock material along with some brazing and shaping. These fabricated samples I still have and the picture is of them alongside the finished cast parts from Longshen.

The samples were sent to Longshen and they have a draftsperson do the working 3D drawings from the samples. The parts were complicated and a lot back and forth was required to get the design sorted. At the time I was learning a lot about the process and language and communications was troublesome but it was all sorted out, mostly with evening emails.

The first samples arrived and from August 2004 I and others have been making lugged stems with these lugs.

However I wish to remind the reader that I do not design and produce these parts or any other frame making parts to tap into a perceived market need of other frame builders. I design and produce the parts for my own in-house production first, because the parts do not exist or maybe the existing parts have shortcomings. I make my living from my hands, so to justify financing the expensive tooling, which was done by borrowing on the equity of the home I then sell the parts to other builders directly or via my agent in the UK and an agent in the USA. It takes about 3-6 years to break even on a part again after the financing interest % is calculated and then one can make a meagre return.

So I happily make stems for the 99% of the Llewellyn owners and over the years I have had many Colnago owners ask me to make a stem for them to fit to their Colnago, I tell them as Ernesto cannot supply you a decent stem to match your bike I will happily make a stem for you and I give them the quoted price, which happens to include a painted Llewellyn frame and fork ��

-

Part 8 B Casting # 1 The Llewellyn Stem lug set

Part 8 B Casting # 1 The Llewellyn Stem lug set

Some pics of a few stems going out the door at the world wide headquarters of Llewellyn Custom Bicycles. No chrome ZONE! Stainless steel only

Another part next week.

-

Llewellyn Stem lug set for a Lucentezza frame set

Llewellyn Stem lug set for a Lucentezza frame set

Another Lucentezza build for some time in 2018, I like to break the the job down into smaller bites, so I did the stem lugs while listening to the Test Cricket today.

-

Re: Llewellyn Stem lug set for a Lucentezza frame set

Re: Llewellyn Stem lug set for a Lucentezza frame set

Originally Posted by

Dazza

[COLOR="Blue"][FONT="Georgia"][SIZE="4"]Another Lucentezza build for some time in 2018, I like to break the the job down into smaller bites, so I did the stem lugs while listening to the Test Cricket today.

Well done! I managed to do very little while listening to the test cricket today, apart from drinking coffee and listening to the test cricket. I enjoy studying your process/progress pictures.

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Likes:

Likes:

Reply With Quote

Reply With Quote

Bookmarks