Dear Guest,

Please register or login. Content don't create itself!

Thank you

-

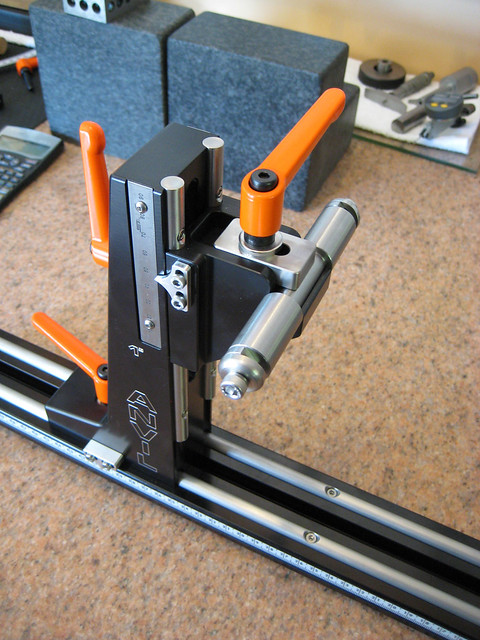

Bringheli Anvil Dummy Axle Adapter

Bringheli Anvil Dummy Axle Adapter

Been wanting to get to this for a while now. I have the Anvil Dummy axles on my fork jig and I like them way better than the Bringheli's.

What I wanted:

-No modification to the Jig (which would allow fellow Bringhelist's to use my adapter)

-Quick Change over

-Obviously use Anvil Dummy Axles

-Keep the Dummy Axle centerlines the same so users can continue to use the Scale for BB Drop.

-Keep the Dummy Axles Offset an easy to remember number.

What I came up with:

It uses a shaft that is turned to the exact diameter of the original Bringheli so it sits in the V the exact same way

This shaft is then flatted to a precise dimension, allowing the mounting of the Adapter Top and Bottom Plates

They function similar to how the Anvil DA is mounted in the Anvil Jig.

The end result is a Anvil Dummy Axle mounted in your Bringheli Jig exactly 50mm on center to the left of the original Dummy Axle.

I'm trying to see if there would be enough interest to send the parts to one of my vendors to have then run. If not I'm only planning on building 3 or 4 sets myself. 2 of which are already spoken for (me and another forum member). Also I'm taking this opportunity to see if anyone has suggestions or input before I start cutting metal.

Thanks - Todd.

-

Re: Bringheli Anvil Dummy Axle Adapter

Re: Bringheli Anvil Dummy Axle Adapter

Looks really nice. If I still had my Bringheli I would want one.

If the hold-down plate was on top would it be easier to remove the frame from the jig with the axle still in the frame? You'd just have to add a correction constant to the BB drop graduation.

-Joel

-

Re: Bringheli Anvil Dummy Axle Adapter

Re: Bringheli Anvil Dummy Axle Adapter

Joel,

I'm going to do a few experiments at home to see how a finished frame comes out of the jig. I can't really remember how I pull it out, since it's not something I really think about when I do it. The hold down plate does slide back on that slot far enough to fully clear the axle however. Thanks for giving me something to think about, adding a correction constant wouldn't be that hard, it would be nice if I had one less thing to think about though!

Thanks again -Todd.

-

Re: Bringheli Anvil Dummy Axle Adapter

Re: Bringheli Anvil Dummy Axle Adapter

it would be more expensive (if you wanted to keep the height the same as the original) but you could make a z-shaped holder that would end up giving you the same setup as the anvil 2011 fork jig, seen here

-

Re: Bringheli Anvil Dummy Axle Adapter

Re: Bringheli Anvil Dummy Axle Adapter

After doing some testing last night, I found the frame comes out of my Jig a lot easier by rocking it back a bit. This is probably because it's been so heavily modified, so for now I'm sticking with the current design.

I had a chance to get started on the prototype that I am making myself.

-

Re: Bringheli Anvil Dummy Axle Adapter

Re: Bringheli Anvil Dummy Axle Adapter

Looks cool, Todd!

My main complaint with the rear end bracket is the V that's cut in the vertical slider piece. Mine wasn't originally milled the best and so the dummy Axle sat on it lower on one side than the other. I have corrected that, for the most part, over the years, but it seems like every time I take the dummy axle out it goes back in slightly different spot. Therefore, for me, it would be cool to see that whole V arrangement eliminated.

I don't mock up chain stay/drop outs on the jig (I do that on an Anvil chain stay mitering fixture), and so having an Anvil dummy axle there hasn't as much benefit for me. However, your idea looks cool and it looks like it will work well. Plz let us know how it goes.

Thanks,

Dave

-

Re: Bringheli Anvil Dummy Axle Adapter

Re: Bringheli Anvil Dummy Axle Adapter

Todd, I would definitely take one. I'm finding out that the Bringheli dummy axel set up needs some refining. Your solution looks great. Any idea how much you would sell them for?

-

Re: Bringheli Anvil Dummy Axle Adapter

Re: Bringheli Anvil Dummy Axle Adapter

Originally Posted by

Dave Anderson

Looks cool, Todd!

My main complaint with the rear end bracket is the V that's cut in the vertical slider piece. Mine wasn't originally milled the best and so the dummy Axle sat on it lower on one side than the other. I have corrected that, for the most part, over the years, but it seems like every time I take the dummy axle out it goes back in slightly different spot. Therefore, for me, it would be cool to see that whole V arrangement eliminated.

I don't mock up chain stay/drop outs on the jig (I do that on an Anvil chain stay mitering fixture), and so having an Anvil dummy axle there hasn't as much benefit for me. However, your idea looks cool and it looks like it will work well. Plz let us know how it goes.

Thanks,

Dave

Dave,

I've never thought about that, I'm curious to see if mine is milled correctly. I'm gonna have to check this out when I get home. Maybe I should just stick to my original plan of replacing the whole back end haha!!

We will see how this works. Thanks for your input as always! You've been a great help since you have so much experience with this jig.

Originally Posted by

Mike Wanner

Todd, I would definitely take one. I'm finding out that the Bringheli dummy axel set up needs some refining. Your solution looks great. Any idea how much you would sell them for?

Mike if the quantities are low, I'll just mill them myself. I just charge material and labor ($30/hour), so this piece took me about 45 mins with blanking the size out and doing all the operations. So this piece I just did would be around $28.00 just to give you an idea. It will be under $100.00 that's for sure.

-

Re: Bringheli Anvil Dummy Axle Adapter

Re: Bringheli Anvil Dummy Axle Adapter

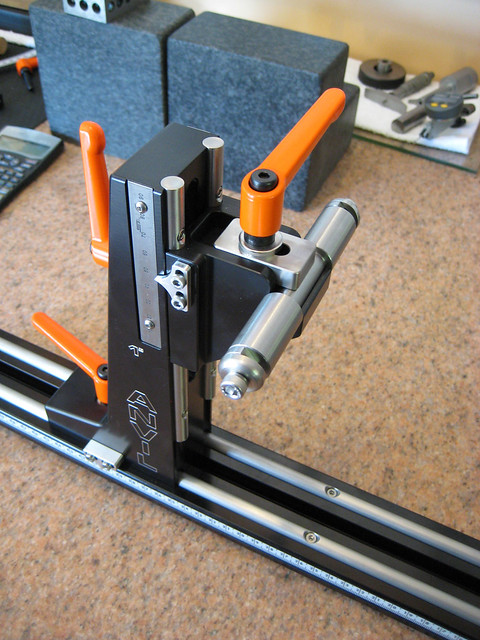

Turning the Intensity up a few notches based on the great Dave Anderson's comments and after talking to a couple other Bringheli users.

Probably going to still offer the first option for the budget conscious user.

-

Re: Bringheli Anvil Dummy Axle Adapter

Re: Bringheli Anvil Dummy Axle Adapter

Whoa....now that is cool!

Where do I sign up?!

Dave

-

Re: Bringheli Anvil Dummy Axle Adapter

Re: Bringheli Anvil Dummy Axle Adapter

Dave, now that is looking better by the moment. Yes I think that would be very reasonable and a great up grade to my Bringheli. Let me know when you get it ready.

Mike

-

Re: Bringheli Anvil Dummy Axle Adapter

Re: Bringheli Anvil Dummy Axle Adapter

And so it begins. Starting off with a set of 4 of these.

Dave, I'm wondering if I can send you one of the initial prototypes. I've been a huge fan of your work for a long time, and I know you know the Bringheli almost better than anyone. I would be honored if you could use it for a bit and give me some feedback? I'm planning on having this done hopefully in the next 2-3 weeks.

Anybody looking to hop on board for a future run better message me or email me at farr.frameworks@gmail.com. The initial 4 are already spoken for.

-

Re: Bringheli Anvil Dummy Axle Adapter

Re: Bringheli Anvil Dummy Axle Adapter

What's the clamping width on those anvil dummies? Been considering something similar for these ubi dummies I have (can't recall their clamp width off the top of my head- maybe 70?). I've got the bugs out of the jig- I think- but like the idea of cotinuity. As it stands, I braze and miter chainstays using the ubi, as the dropouts are held in phase. Switch over to the jig dummy only when it's time to tack the rear triangle.

-

Re: Bringheli Anvil Dummy Axle Adapter

Re: Bringheli Anvil Dummy Axle Adapter

I don't have one in my hands yet but they are 2.5" wide with a 0.500 nominal OD in the center section according to Don

-

Re: Bringheli Anvil Dummy Axle Adapter

Re: Bringheli Anvil Dummy Axle Adapter

Originally Posted by

ToddFarr

Turning the Intensity up a few notches based on the great Dave Anderson's comments and after talking to a couple other Bringheli users.

Probably going to still offer the first option for the budget conscious user.

Now you're talking!! I would buy that. I currently use a 3-way clamp to hold the Anvil axle. IIRC, the offset is around 6 mm from the original. I tack one stay/bb in the fixture and then go to the surface plate. Huge pain.

-

Re: Bringheli Anvil Dummy Axle Adapter

Re: Bringheli Anvil Dummy Axle Adapter

Hi Todd,

Just saw your post. PM sent.

Thank you,

Dave

-

Re: Bringheli Anvil Dummy Axle Adapter

Re: Bringheli Anvil Dummy Axle Adapter

Just a little heads up on where I am at with this....

Anyways, it seems the main complaint on the Bringheli back in is inaccuracy, which I have narrowed down to 2 main problems.

The main support bar has quite a bit of flex to it, and is machined pretty poorly, at least on mine.

The second problem is like most people have stated the axle is held by a small V with limited surface contact. Any deviation in this V skews the axle requiring compensation by the builder.

I've solved these two problem by creating stiffer system that allows for easier adjustments by the user. By limiting the length of the bar that supports the dummy axle and stacking thicker components at the contact points on the jig.

It solved one problem but created another. When you stack parts you can no longer use stock material, because stock material may measure correct on the edges often times it bows down in the middle. Also you are stacking tolerances, so by the time you get out to the jig centerline it may be up to 0.060" off.

The second problem is making sure all components are bolted together correctly. Bolts and clearances have a lot of slop, so I've added precision dowel pins in the appropriate, and important locations to ensure that every bolting location is a perfect fit.

You can see the two dowel pins through the transparent part. These holes are designed to be a press fit in one part and a super tight slip fit on the other. So the parts can be removed if needed, but will be able to be reassembled perfectly afterwards.

To make the back end this accurate some increased costs are involved. That being said, the cost for this backend mod is going to be $450.00 if only 5 people are involved, if I can get 10 I can cut the cost down to $340.00.

Anyways you guys still interested?

Thanks - Todd.

-

Re: Bringheli Anvil Dummy Axle Adapter

Re: Bringheli Anvil Dummy Axle Adapter

-

Re: Bringheli Anvil Dummy Axle Adapter

Re: Bringheli Anvil Dummy Axle Adapter

The centerline of the jig is supposed to be 8.500" right? What does your guys measure? I was pretty sure they are all the same then I saw this post. Bike From Scratch › Aligning the rear end on a Bringheli jig

He's calling out 213mm which is 8.3858"...which seems weird.

-

Re: Bringheli Anvil Dummy Axle Adapter

Re: Bringheli Anvil Dummy Axle Adapter

Similar Threads

-

By Archibald in forum The Frame Forum@VSalon

Replies: 1

Last Post: 04-17-2011, 10:03 AM

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Likes:

Likes:

Reply With Quote

Reply With Quote

Bookmarks