Diy dro

Diy dro

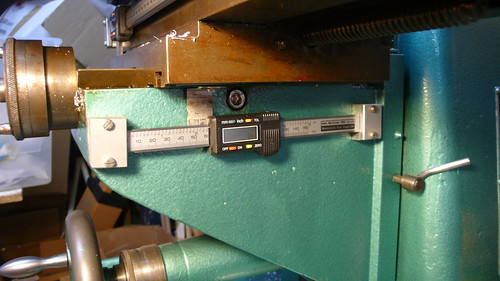

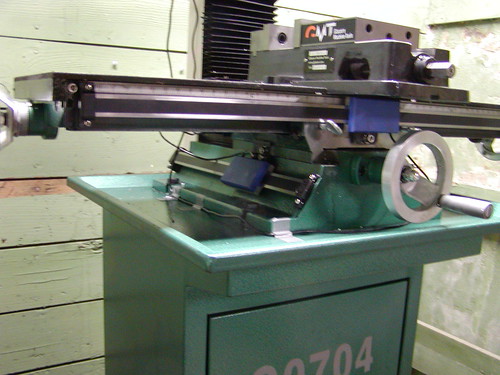

So after blowing a huge wad on gear this last summer/fall, I'm hesitant to spend too much more money, but one of the things I'd like to do is get a two-axis DRO for my benchtop mill. In looking at the prices, I'm utterly appalled at what I'm finding out there. (Also, finding glass scales that will fit a Grizzly G1005Z ain't easy.)

I've been noodling with taking a DIY approach to this -- I have the coding and electronics skills to do this, and I'm currently trying to decide between using an Arduino and a Raspberry Pi (Rev B) for the project. Right now, I'm leaning toward the latter, because in-theory I could use it to run a CNC setup, too. What I am wondering about is scales.

So I have the options for going with glass or magnetic, though I'm not completely clear on the pros/cons of each, and I'm looking for ones that have either USB or serial port outputs. Can anyone provide some insights?

(And just as an aside, if I decide to do this, I'll be open souring any code I write under the GPL, and will be blogging a complete write-up of the process of building one so it can be replicated by anyone who wants to do it.)

So. Educate me on the scales -- which way to go, and where the f*** can I find them for sale online?

Ita erat quando hic adveni.

www.danbailey.net

Likes:

Likes:

Reply With Quote

Reply With Quote

Bookmarks